Australian robotic engineering company CSF Robotics has become a reseller for Robotmaster – a product of Jabez Technologies which seamlessly integrates CAD/CAM based robot programming, simulation and program generation.

According to the company’s blog post, the agreement will see the Melbourne-based company supply and implement Robotmaster software for end-users who already have existing equipment as well as providing a complete turn-key (hardware and software) solution with their integrated robotics manufacturing cells.

“Robotmaster is a revolutionary approach to robot programming, providing the most advanced technologies to achieve precise tool motion control for both tool-on-robot and part-on-robot applications. In conjunction with the powerful off-line programming tools of Robotmaster, we can take our customer’s automation systems to the next level,” said Steph Gooden of CSF Robotics.

Jabez Technologies’ Robotmaster provides innovative new tools to effortlessly optimise robot programs producing error-free robot paths avoiding singularity zones and collisions, working around joint and reach limitations and optimising tool orientations along the entire trajectory.

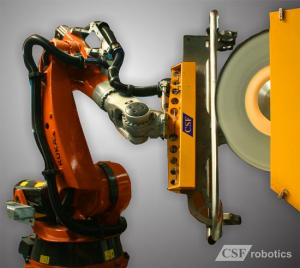

It is ideally suited to program robots for such tasks as trimming, 3D machining, de-burring, polishing, welding, dispensing, grinding and painting, and supports most industrial robot models.

“One of the reasons we developed Robotmaster was to provide robot integrators easy programming tools, required for short-batch manufacturing, helping them to enter into these emerging markets. We are pleased to be working with a partner like CSF Robotics with their extensive experience and proven track record, in a wide variety of industries and robotic applications,” said Chahe Bakmazjian, President of Jabez Technologies.

CSF Robotics is a Melbourne-based company which specialises in custom robotic automation, surface finishing, machining and high-end materials processing. It provides turn-key automation solutions to a wide variety of industries and robotic applications including trimming, cutting, machining, de-burring, fettling, welding, linishing, polishing, buffing, assembly, packaging, quality assurance and much more.