Media Release

Do you know what your workers are breathing in?

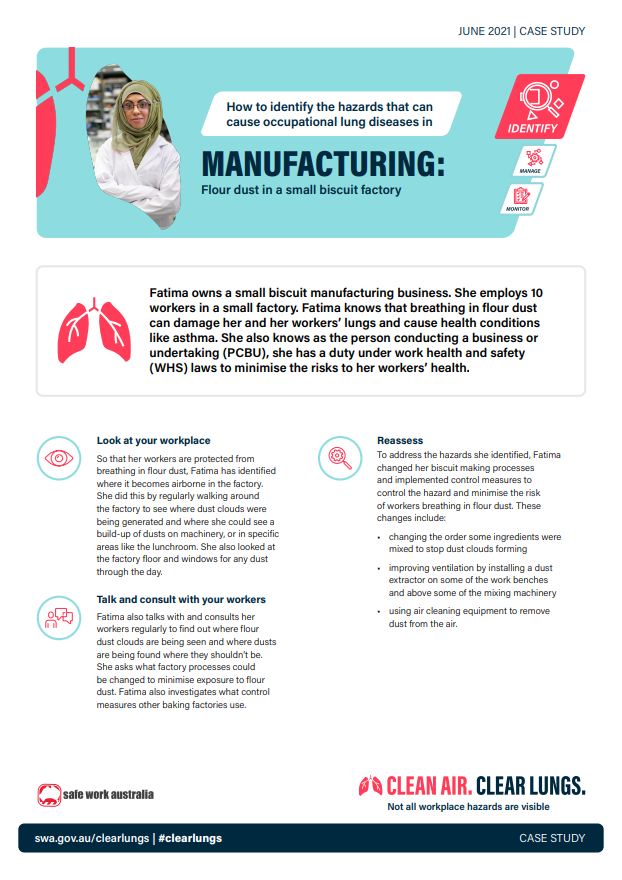

Safe Work Australia has launched a national campaign to raise awareness of occupational lung diseases and to educate persons conducting a business or undertaking (PCBUs) on what they can do to manage these risks at work.

Safe Work Australia CEO, Michelle Baxter said “The Clean Air. Clear Lungs. campaign targets industries where there is a high risk of workers contracting an occupational lung disease such as construction, manufacturing, agriculture and those who work with engineered stone.”

“The manufacturing industry covers a broad range of workers, trades and administration staff – it’s important to remember that everyone could be exposed to hazards in the air.”

“Occupational lung diseases are serious conditions, but they are entirely preventable. As a PCBU, you have a duty to protect the health and safety of your workers and the first step is to identify if hazards exist at your workplace,” Ms Baxter said.

In manufacturing, hazardous dusts, gases, fumes and vapours can be created when:

- welding and spray painting

- making rubber, foams and plastics, or when using paints, glues and varnishes with isocyanates

- using flour and other materials

- working with resources technology, mineral processing, medical and pharmaceutical supplies

“Once PCBUs have identified hazards, they then need to undertake a risk assessment and implement control measures to protect workers from developing an occupational lung disease.”

“The best control measure is to eliminate the risk altogether, however if that isn’t possible it is essential to apply the most appropriate control measures to manage the risk,” Ms Baxter said.

Effective control measures can include:

- Substitution

- using ingredients or products that produce less dust or include a stabiliser to minimise fume and vapour production

- replacing high toxicity paints, glues and varnishes with lower toxicity options

- Isolation

- isolating dust, fume and vapour generating work processes withing a closed room with restricted access

- Engineering

- using local exhaust ventilation or fume cupboards to stop dusts, fumes and vapours from reaching a worker’s breathing zone

- automating tasks that generate dusts, gases, fumes and vapours

- using industrial vacuum cleaners with appropriate dust filtration during clean-up

- Administrative

- shift rotation policies and designated change areas

- using appropriate personal protective equipment, including respiratory protective equipment

Safe Work Australia’s Clean Air. Clear Lungs. campaign is supported by work health and safety regulators and other stakeholders to increase awareness of occupational lung diseases.

For more, see the campaign website: https://www.safeworkaustralia.gov.au/clearlungs

For manufacturing resources, including infographics, checklists, and case studies: https://www.safeworkaustralia.gov.au/clearlungs/resources?f%5B0%5D=tag_by_industry_business%3A445