Researchers from the Manchester Metropolitan University are working on developing longer-lasting batteries for the smartphones of the future and they want to 3D print them using graphene ink.

Image credit: www.mmu.ac.uk

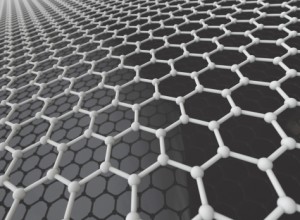

We all know graphene is widely praised for its suitability for use in batteries due to its amazing conductivity. Graphene was discovered at the University of Manchester in 2004. It is 200 times stronger than steel and is a highly efficient conductor of heat and energy.

“Energy storage systems (ESS) are critical to address climate change and, as clean energy is generated through a variety of ways, an efficient way to store this energy is required. Lithium and sodium ion batteries and super/ultracapacitors are promising approaches to achieve this. This project will be utilising the reported benefits of graphene – it is more conductive than metal – and applying these into ESS,” said Prof Banks, Associate Dean for Research and Professor in Electrochemical and Nanotechnology.

“In addition to the choice of material, the overall architecture of ESS is of critical importance. The architecture of ESS can be improved through the use of 3D structures, which have high surface areas, good electrical properties and hierarchical pore structures/porous channels. We’re trying to achieve a conductive ink that blends the fantastic properties of graphene with the ease of use of 3D printing to be manipulated into a structure that’s beneficial for batteries and supercapacitors.”

Professor Banks is leading the new project to develop a desktop printer to create batteries, supercapacitors and energy storage devices for phones or tablets, and solar, wind and wave power storage.

According to him, the process of 3D printing needs to be refined as each layer that is printed has to be cured an hour before another layer can applied.

“We need to figure out a way to cure it directly, possibly by shining a UV light on to it, as anything above a micron level takes a long time. Ideally, we could have the brilliant scenario where you just plug in and go – printing whatever structure you want out of graphene from a machine on your desk,” he said.

Funded by £500,000 from the Engineering and Physical Sciences Research Council (EPSRC), the project runs for three and a half years.