Who doesn’t want an instant manufacturing machine at home? Any “Star Trek” fan dreams of having his own Replicator. For those of you who aren’t that well acquainted will the cult sci-fi show, a Replicator is a machine capable of creating and recycling objects. In the show, replicators were firstly used to instantly synthesise meals on demand, but in later series they were used to replicate parts, clothes, tools and so on.

Image credit: cfg.mit.edu

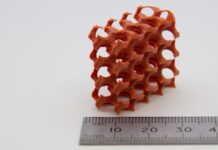

A couple of years ago, such machines were simply an idea. Now, researchers at the Massachusetts Institute of Technology (MIT) Computer Science and Artificial Intelligence Laboratory (CSAIL) are working on a 3D printer that is capable of printing with 10 different materials within a single build, with a current material library consisting of 15 possibilities.

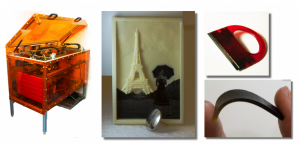

MIT CSAIL’s MultiFab 3D printer is a huge step towards developing a real Replicator. It can print everything from plastic housings, to lenses, to even circuit boards, wiring, and so on.

Some of the materials included within the library are a rigid material (RIG), elastic material (ELA), high refractive index material (HR), low refractive index material (LR), and a support material (SPT)–and this library should continue to expand substantially with further research, the scientists state.

The vision-assisted multi-material 3D printer can also print incredibly fine details, with layer heights as small as 13 microns.

“It has the potential to accelerate innovation – engineers and hobbyists will have the power to create objects that have been previously impossible or very difficult to fabricate. It will also give them the opportunity to iterate over their designs inexpensively and quickly. Multi-material 3D printing will also impact the general population by allowing mass customisation of personalised products,” state MIT researchers Pitchaya Sitthi-Amorn, Javier Ramos and others in their paper titled “MultiFab: A Machine Vision Assisted Platform for Multi-material 3D Printing.”

“Our current system has a bill-of-materials of less than $7,000, and the estimated cost of the printing materials is around $20 per kilogram. The current platform is built exclusively from low-cost, commercial off-the-shelf components. The use of a computer vision feedback loop simplifies the design and compensates in software for hardware deficiencies. Our system also pioneers inexpensive and safe LED curing (no other 3D printer we know of uses it) and a simple material feeding system. Our system adapts consumer printheads for polymer 3D printing.”

The researchers have already conducted numerous tests and have successfully printed a wide array of objects, such as an LED with an integrated lens, complex meta-materials, privacy screens for smartphones, optical fibre bundles and so on.

It’s no Replicator, but it’s a great start and an amazing accomplishment.

Check out MIT CSAIL’s MultiFab 3D printer in action in the video below.