Researchers from RMIT, RUAG Australia and the Innovative Manufacturing Cooperative Research Centre (IMCRC) are collaborating on a 2-year project for 3D printing aircraft parts using new laser technology.

Led by RMIT Professor Milan Brandt, the team are using are using ‘laser metal deposition’ technology to build and repair steel and titanium parts for defence force aircraft.

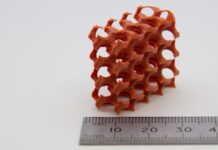

The technology works by feeding metal powder into a laser beam which then deposits material in a precise, web-like formation across a surface. It can be used to both 3D print new or fix parts existing parts with a bond that is – in some cases – even stronger than the original.

Professor Brandt says the concept is proven, adding that the prospects for its successful development are ‘extremely positive’.

“It’s basically a very high-tech welding process where we make or rebuild metal parts layer by layer,” explains Brandt.

RUAG Australia’s Head of Research and Technology, Neil Matthews, says the technology could completely transform the concept of warehousing and transporting for defence and other industries by eliminating the need for replacement parts storage.

He says the technology will reduce the cost of replacing damaged aircraft parts for the Australian Air Force, which is estimated to be more than $230 million a year.

“Instead of waiting for spare parts to arrive from a warehouse, an effective solution will now be on-site,” says Matthews.

“For defence forces this means less downtime for repairs and a dramatic increase in the availability and readiness of aircraft.”

CEO and Managing Director of the IMCRC, David Chuter says the technology is also applicable to many other industries.

“The project’s benefits to Australian industry are significant,” says Chuter.

“Although the current project focuses on military aircraft, it is potentially transferable to civil aircraft, marine, rail, mining, oil and gas industries.”

“In fact, this could potentially be applied in any industry where metal degradation or remanufacture of parts is an issue.”