Johnson Matthey (JM) has announced the opening of a new state-of-the-art ceramic 3D printing facility in Royston, UK.

The company, which produces bespoke ceramic products with flexible geometries, said the new R&D laboratory will improve its understanding of characterising powders and inks, allowing faster development and more effective solutions for customers.

“This new laboratory is a great step forward for Johnson Matthey,” said Research Group Leader, Mr Sam O’Callaghan.

“The cutting-edge technology will help us develop our 3D printing capabilities and offer customers truly bespoke solutions.”

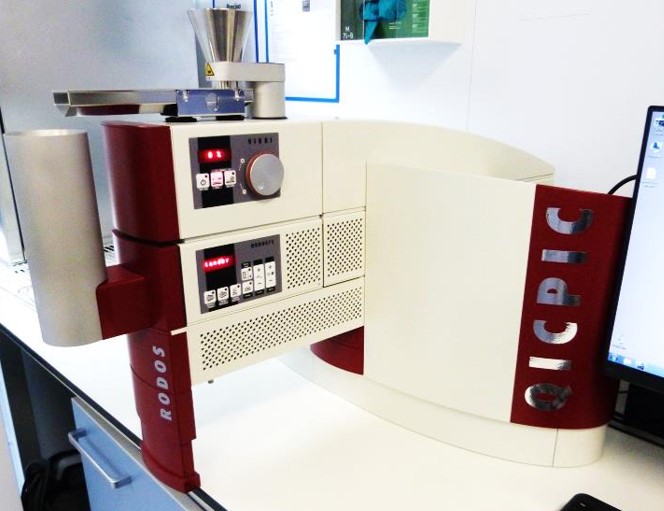

The new facility features QiCPic image analysis sensor, which allows both particle size distribution and shape to be measured simultaneously in a dry atmosphere similar to the ‘in use’ environment.

It also includes the Freeman FT4 – an advanced piece of equipment that allows 7 different test types, resulting in 21 different powder properties.

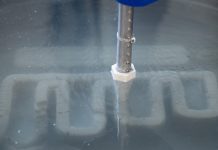

According to JM’s statement, the new lab will improve ink characterisation techniques using a PixDro ink jet printer, fitted with same printhead system installed across all of the R&D prototype and pilot plant printers.

“This allows diversity, as well as cost saving experiments, assessing alternative suppliers and reagents,” reads the statement.

In addition, the new lab features a mixer torque rheometer that allows powder-ink interactions to be measured.

“This enables us to define the ideal printer settings prior to printing as well as giving us a background understanding of why certain powders perform differently to others,” it says in the statement.

“The overall aim of this new facility is to build upon our understanding of 3D printing, improve our processes and help create effective applications for our product.”