More advances are being made in the world of 3D printing as two teams in China unveiled their new 3D bioprinters which print actual living tissue from cultivated cells.

Basically instead of using layers of plastics or metal powder, the technique uses layers of biological building blocks to create real, living tissue.

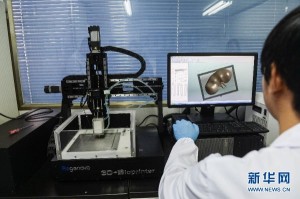

Chinese researchers led by Xu Ming-En from the Hangzhou Dianzi University have developed China’s first 3D bioprinter they named Regenovo.

In a feature on 3D Printer World, Mr. Xu explained the process of how they were able to print multiple tissue samples including liver and human ear cartilage.

“Before printing you can preview the print path of each layer and determine suitable speed and temperature. But the system is not yet smart enough; sometimes you have to control it manually,” says Mr. Xu.

He says the process of producing a mini liver or an ear about four to five inches in length takes about 40 minutes to an hour. According to 3D Printer World, the damage rate for the Regenovo printing is quite low and 90% of the cells survive the process, allowing it to survive for up to four months. The machine can print in aseptic conditions and includes temperature control cartridges allowing it to print in temperatures ranging from 23° F to 500°F.

In a related article on 3Ders.org Mr. Xu explained why the printed tissue has to undergo a time for solidification.

“The 3D printed tissue is very soft, it needs a cross-linking agent to assist solidification and then be placed in the incubator.”

A sheet of water-based hydrogel is deposited first onto a printing surface, then followed by a circle of cells. The process is then repeated layer by layer until a stack of sheets – the new organ is finished. While the concept is still in its early stages Mr. Xu hopes that in the next few years the technology may be able to print out liver and kidney that can be transplanted into human body. He predicts fully functional printed organs will be possible in the next ten to twenty years.

Meanwhile another company in China is making headway in the biological 3D printing arena.

This week Unique Technology from Qingdao, Shandong province introduced their 3D bio printer which they called “Re-human”.

Re-human can print down to 15 microns and operate with temperatures ranging between 0 and 300 degrees Celsius.

According to 3Ders.org, the 3D printer has successfully produced scaffolds and bones with different precision and shapes using cultivated cells. Notably, Re-human was able to print scaffolds for heart tissue constructs, which has a great potential to be used in cardiac repair. Theoretically a biodegradable 3D printed scaffold can be absorbed by the body a year after it has been implanted.

The Re-human developers will soon submit the 3D printed scaffolds and bones for clinical trials.