Manufacturing research at IMDEA Materials Institute has demonstrated a new way to increase the flexibility of 3D-printed nickel–titanium alloys, using woven architectures to overcome limitations associated with additive manufacturing.

In a study conducted with the Technical University of Madrid (UPM) and published in Virtual and Physical Prototyping, researchers reported that highly deformable, interwoven nitinol structures can achieve mechanical performance not previously possible with conventional 3D-printed approaches.

IMDEA Materials Institute said nickel–titanium alloys, commonly known as nitinol, are widely used for their superelastic and shape-memory characteristics, especially in biomedical devices and other high-performance engineering applications.

The institute noted, however, that when nitinol is manufactured using laser powder bed fusion (LPBF) – the most commonly applied additive manufacturing method for the alloy – the resulting components generally exhibit reduced elasticity compared with those produced through established industrial manufacturing processes.

“While LPBF remains the gold standard of nitinol additive manufacturing, the shape-memory and superelastic properties of these additively manufactured NiTi parts do not yet match those achieved with more conventional industrial processes,” said Carlos Aguilar Vega, a researcher at IMDEA Materials and UPM, and a co-author of the study.

Rather than focusing solely on material optimisation, the research team adopted a design-centred manufacturing approach, using geometry to enhance mechanical performance.

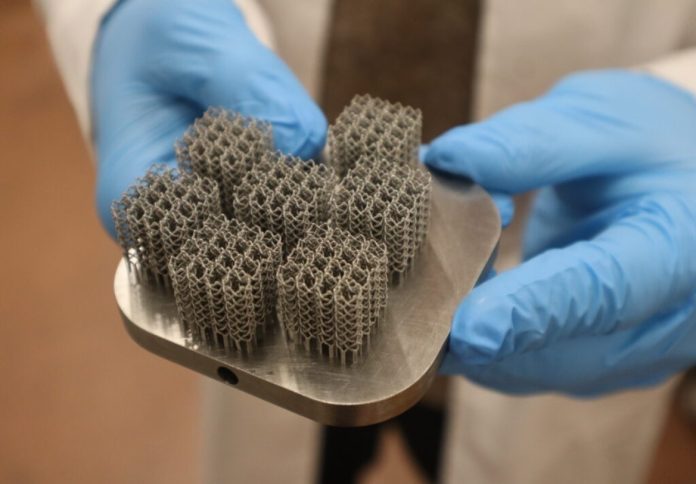

The work focused on complex woven forms, including meshes, rings and tubular structures, produced directly through additive manufacturing.

“These were some of the most complex-shaped woven nitinol structures ever created,” said Prof. Andrés Díaz Lantada of UPM and IMDEA Materials Institute. “They demonstrate the possibility of achieving self-supported NiTi wovens via LPBF techniques.”

According to the researchers, mechanical testing showed that properties such as stiffness, load-bearing capacity and energy absorption could be adjusted across several orders of magnitude through design alone.

Computed tomography was used to compare printed components with their digital models, confirming the accuracy and robustness of the manufacturing process.

“This work represents the first demonstration of design-based optimisation of additively manufactured superelastic nitinol,” Aguilar Vega said, adding that architectural design can help mitigate mechanical drawbacks inherent in current additive manufacturing methods.

The research was carried out by a joint IMDEA Materials and UPM team and supported by the Comunidad Autónoma de Madrid through the iMPLANTS-CM research and innovation programme.