After being selected by NASA to deliver cargo to the International Space Station – which is quite an achievement as well – global leader in aerospace and defence technologies Orbital ATK announced that it successfully tested a 3D printed hypersonic engine combustor.

About a week ago, the company announced that it was awarded an 8-year contract by NASA to provide commercial cargo delivery and disposal services to and from the International Space Station (ISS).

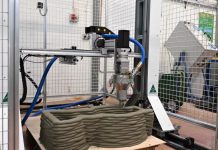

On Monday, Orbital ATK said that it successfully tested a 3D-printed hypersonic engine combustor at NASA Langley Research Centre produced through an additive manufacturing process known as powder bed fusion (PBF).

PBF, also known as Selective Laser Sintering (SLS), is actually a metal additive manufacturing technique that incorporates the use of a high power laser to sinter metal powders one layer at a time to build a solid 3D metal structure.

Image credit: NASA

The combustor was subjected to a variety of high-temperature hypersonic flight conditions over 20 days.

In a media release, the company stated that it wanted to ensure that the PBF-produced part would be robust enough to meet the objectives of the mission.

“Additive manufacturing opens up new possibilities for our designers and engineers,” said Pat Nolan, Vice President and General Manager of Orbital ATK’s Missile Products division of the Defence Systems Group.

“This combustor is a great example of a component that was impossible to build just a few years ago. This successful test will encourage our engineers to continue to explore new designs and use these innovative tools to lower costs and decrease manufacturing time.”