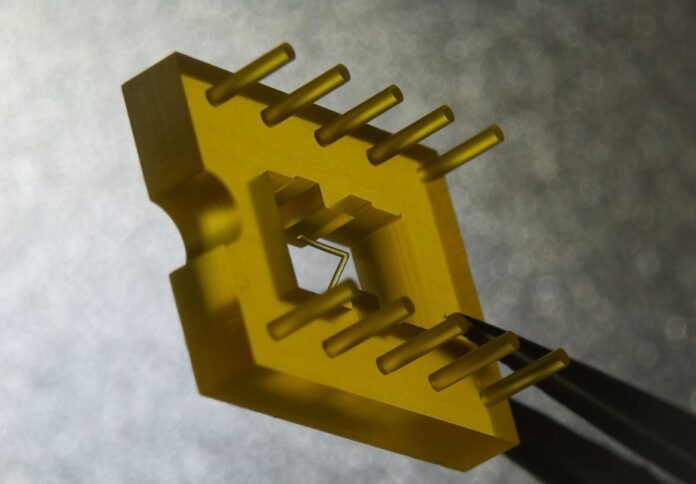

Microfabrication start-up Horizon Microtechnologies has developed a template-based 3D microfabrication technology suited as a post-printing treatment for micro-additive manufacturing-derived parts.

Company CEO Andreas Frölich said now that its technology has reached the market, it may contribute to the first time more manufacturing adaptability in the production of electrodes, electrical contact pins, 3D microfluidic devices, and optical packaging.

“Using micro-AM can in many instances be cheaper and quicker than using conventional manufacturing processes, and stimulates design freedom and allows the production of parts and components with geometric complexity hitherto impossible,” Frölich explained.

The CEO further pointed out that the technology is important in the automated assembly of optoelectronic components (such as bare laser diodes), where it is necessary to handle components that are small, mechanically delicate, static-discharge sensitive and have several ‘no-touch’ areas.

Having collaborated on product development with its clients, the company emphasised that form, function, and material are all taken into account in consultation with the customer.

The 3D microfabricated template determines the net shape of the final part, while post-processing steps achieve the final functionality, the company said.

Meanwhile, Frölich argued that there is no doubt additive manufacturing (AM) and micro-AM have changed how different industries make end-use parts for a variety of applications.

“The dawn of ultra-precise micro-AM technologies recently opened up the advantages of AM for micro manufacturers, and by developing our microfabrication technology we have extended the areas in which AM can have a positive influence,” the CEO noted.

In addition to the mentioned features, the post-processing method can also uniformly coat problematic sections, such as long, narrow channels and undercuts, with a conductive layer, either completely or selectively.

The company added that microfabricated 3D templates can also be coated with metal oxides to make parts suitable for use in aggressive chemical environments and, in some cases, to significantly increase resistance to high temperatures and mechanical stresses.

“Effectively what we do at Horizon is open up the resolution, tolerances and other attractive features of polymer micro-AM for applications where it is otherwise not appropriate due to the polymer’s material properties,” Frölich concluded.