IperionX, a leader in sustainable, circular titanium supply chains, has acquired the assets and intellectual property portfolio of Blacksand Technology LLC.

This acquisition grants IperionX exclusive commercial rights to key patents and proprietary technologies, including Green Rutile, Alkaline Roasting Hydrolysis, Hydrogen Assisted Metallothermic Reduction (HAMR), and Hydrogen Sintering and Phase Transformation.

The newly acquired technologies provide significant advantages over the traditional Kroll titanium production process, the company said in an ASX announcement.

They are expected to reduce energy consumption, lower capital expenditure, shorten cycle times, increase product yields, and allow the use of 100 per cent scrap titanium or upgraded titanium minerals as feedstocks.

These advancements align with IperionX’s mission to create an innovative, sustainable ‘end-to-end’ American titanium supply chain.

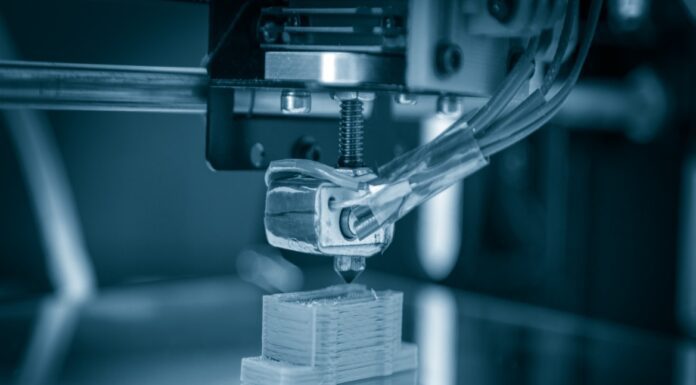

IperionX’s strategy spans from the production of US-sourced titanium minerals to the manufacturing of high-performance, lower-cost titanium metal forged parts.

The company’s proprietary technologies are designed to produce a wide range of high-strength forged titanium alloys, offering class-leading sustainability and superior energy efficiencies when compared to current industry methods.

Anastasios (Taso) Arima, CEO of IperionX, emphasised the significance of the acquisition, stating, “The acquisition of the award-winning intellectual property portfolio is an important milestone for IperionX – delivering direct control of the technologies and innovations that underpin our plans to re-shore an end-to-end, lower-cost U.S. titanium supply chain that is critical to America’s economic and national security.”

The integration of these technologies positions IperionX to deliver considerable value by upgrading raw titanium materials into finished products, bypassing the need for traditional titanium metal sponge and ingot production.

This shift allows for the direct manufacturing of higher-value titanium products starting from the billet stage.

IperionX said it is already advancing its plans for commercialization at its Titanium Manufacturing Campus in Virginia.

In August 2024, the company commissioned a new HAMR furnace and completed the first titanium deoxygenation production run.