IperionX has signed a Test Services Agreement and Statement of Work with the US Army Combat Capabilities Development Command Ground Vehicle Systems Center (DEVCOM GVSC).

In an ASX announcement, IperionX said the agreement will focus on the metal characterisation and ballistic testing properties of the company’s high-strength titanium plate components.

DEVCOM GVSC may forward the results to specific US DoD contractors who are US original equipment manufacturers (OEMs) of US Army ground vehicles for consideration in future ground vehicle designs.

Known US Army ground vehicle contractor OEMs include General Dynamics Land Systems, BAE Systems, American Rheinmetall Defense, Oshkosh Corporation, and AM General.

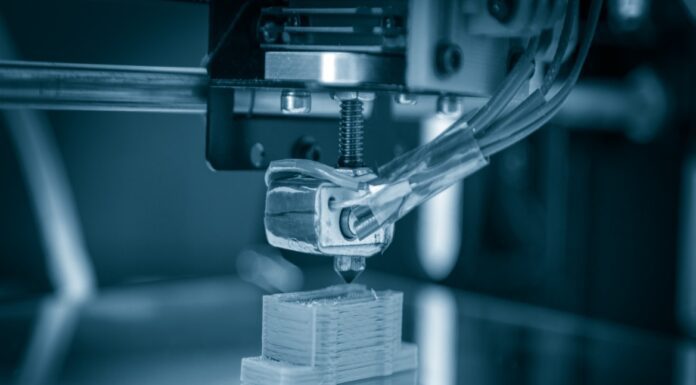

In particular, the titanium plate for US Army ballistic tests will be manufactured using powder metallurgical technologies and IperionX’s advanced titanium angular powder.

IperionX will also use its patented Hydrogen Sintering and Phase Transformation (HSPT) technologies to improve performance and durability, a cutting-edge technique aimed at enhancing the microstructure of titanium to deliver strength and fatigue properties comparable to wrought titanium alloys.

To date, the United States has very limited domestic primary titanium metal (titanium sponge) capacity and currently imports over 95 per cent of the titanium sponge required for the US defence sector.

The ASX-listed company said it intends to strengthen the domestic titanium supply chain for critical defence systems and re-shore a fully integrated titanium supply chain to the US in order to decrease the acute reliance on titanium imports from other countries.

Brandon Pender, Associate Director GVME, GVSC Head of Materials and Manufacturing, stated that the organisation is investigating the use of advanced manufacturing and titanium to help improve corrosion mitigation and light-weighting in Army ground vehicles.

“The potential to produce titanium plate, with all of its capabilities, that is cost-competitive with aluminium and steel only helps us improve the operational performance and readiness of Army ground systems,” Pender said.

Meanwhile, IperionX CEO Anastasios Arima expressed his delight in working with DEVCOM GVSC to evaluate titanium products for use in the US Army vehicles on the ground.

“Titanium for the US defence sector is currently sourced over long distances from foreign nations. IperionX plans to re-shore a lower cost and more sustainable fully integrated U.S. titanium supply chain that is critical to America’s economic future and national security,” Arima concluded.