Li-S Energy has produced Australia’s first lithium metal foils at its advanced battery cell facility in Geelong, marking a key step in building sovereign battery manufacturing capabilities.

The milestone was achieved ahead of schedule under a $1.76 million matched funding grant from the Australian Government’s Industry Growth Program (IGP), aimed at boosting local capability in high-purity lithium metal processing, the company revealed in an ASX announcement.

The new domestic capability is expected to improve supply chain resilience, eliminate reliance on imported lithium foils, and reduce costs, delays and quality risks.

According to Li-S Energy, the move also positions the company to pursue revenue opportunities in global markets seeking high-purity battery inputs.

“This is a transformative moment for Australia’s battery industry,” said Dr Lee Finniear, CEO of Li-S Energy. “We are proud to be the first company in the country to produce lithium foils – a critical component for the future of high energy density batteries. By reducing dependence on overseas supply chains, we substantially improve our cost base, enhance cell quality, and support the resilience of Australian manufacturing.”

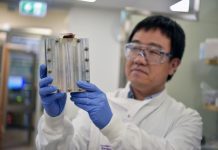

The company confirmed it had installed new lithium extrusion equipment and successfully produced its first 100-micron thick pure lithium metal foils.

Li-S Energy said this in-house production enables tighter control over foil thickness and purity, helping to improve the performance, throughput and safety of its battery cells.

“Lithium metal foils are essential for delivering the high energy density performance we target in our lithium-sulfur and lithium-metal batteries,” said Dr Steve Rowlands, Chief Technology Officer at Li-S Energy.

“By producing foils in-house, we have tighter control over thickness, purity and handling conditions – all of which are critical for performance and safety.”

Li-S Energy is now entering the next phase of the IGP project, which involves installing equipment to roll, laminate and coat the lithium foils.

This expansion is expected to broaden the company’s product range and support the commercialisation of its proprietary nano-material coating technologies.

The company has also opened access to its Australian-made lithium foils for research institutions and companies undertaking R&D in battery technology.