Engineers at the Massachusetts Institute of Technology (MIT) have developed a new 3D printing technique designed to reduce material waste and improve the efficiency of printing complex structures.

The method involves a resin that responds differently depending on the light it is exposed to. When cured with ultraviolet (UV) light, the resin forms a durable solid suitable for the final structure.

When exposed to visible light, it becomes a weaker solid that dissolves easily in certain solvents. This dual-phase capability enables support structures to be removed without manual effort and allows the material to be reused.

The technique builds on vat photopolymerisation, a widely used form of 3D printing in which a liquid resin is hardened layer by layer using patterned light.

In conventional processes, support structures are printed alongside the final product to maintain stability during fabrication. These supports are typically removed by hand and discarded after printing, contributing to waste.

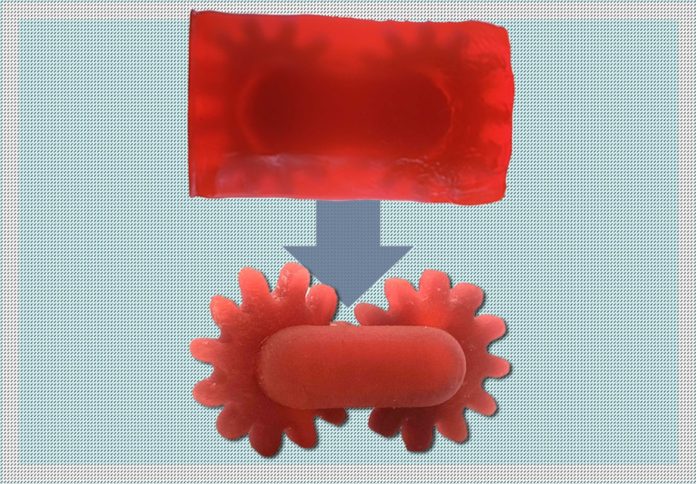

The MIT research team developed a new resin formulation that forms both structural and dissolvable materials in a single printing process.

By directing UV and visible light onto specific areas of the resin, the printer can create the desired object and its temporary supports simultaneously. Once printing is complete, the supports can be dissolved in a solution, such as baby oil or even the base liquid resin, allowing for potential recycling of the material.

The method was used to fabricate detailed items including gear mechanisms, lattice structures, and interlocking components. According to the researchers, this approach may be suitable for producing customised parts such as dental implants, hearing aids, and other medical or mechanical components.

“You can now print— in a single print — multipart, functional assemblies with moving or interlocking parts, and you can basically wash away the supports,” said MIT graduate student Nicholas Diaco. “Instead of throwing out this material, you can recycle it on site and generate a lot less waste.”

The study, published in Advanced Materials Technologies, was conducted by Diaco and co-authors Carl Thrasher, Max Hughes, Kevin Zhou, Michael Durso, Saechow Yap, Professor Robert Macfarlane, and Professor A. John Hart, head of MIT’s Department of Mechanical Engineering.

To ensure the printed structures could withstand post-processing, the researchers added a third monomer to strengthen the UV-cured phase.

This adjustment improved the structural integrity of printed parts produced using lower-intensity UV light from standard 3D printers.

“With all these structures, you need a lattice of supports inside and out while printing,” Diaco said. “Removing those supports normally requires careful, manual removal.”

Professor Hart said the team aims to further develop the process by exploring new resin formulations and automation techniques.

“We’ll continue studying the limits of this process, and we want to develop additional resins with this wavelength-selective behavior and mechanical properties necessary for durable products,” he said.

“Along with automated part handling and closed-loop reuse of the dissolved resin, this is an exciting path to resource-efficient and cost-effective polymer 3D printing at scale.”

The research was supported by the Centre for Perceptual and Interactive Intelligence (InnoHK) in Hong Kong, the US National Science Foundation, the US Office of Naval Research, and the US Army Research Office.