Researchers from the University of Texas at Austin and Sandia National Laboratories have developed a new 3D printing method that allows objects with very different physical properties to be created within a single structure using relatively inexpensive equipment and widely available materials.

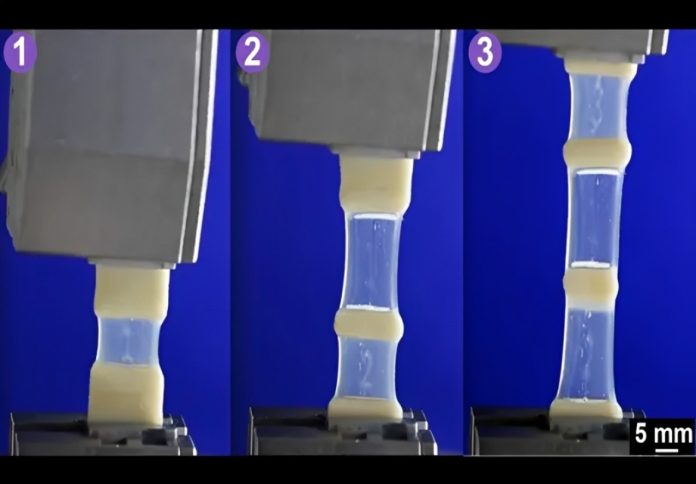

In a media release, the university said the method, described in the journal Science, allows hardness, flexibility and transparency to be controlled at a fine scale, enabling these properties to vary across different regions of a single printed object.

The research team said this level of control could make it possible to produce detailed and realistic replicas of complex structures, including parts of the human body, using standard digital light processing or liquid crystal display 3D printers.

Zak Page, an associate professor of chemistry at the University of Texas at Austin and an author of the paper, said the approach works by regulating molecular order during the printing process.

By adjusting the intensity of light projected onto a liquid resin, the researchers can change the mechanical and optical properties of the material as it solidifies. Page said the ability to achieve this using a simple and inexpensive feedstock was a key feature of the technique.

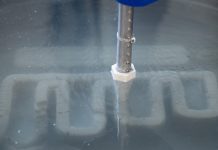

The process, known as Crystallinity Regulation in Additive Fabrication of Thermoplastics, or CRAFT, uses a commonly available liquid resin called cyclooctene.

During printing, a series of grayscale images is projected onto a platform that moves through the resin, forming an object layer by layer. Each layer is microscopically thin, allowing fine-grained control over the structure and properties of the finished part.

One potential application highlighted by the researchers is the production of anatomical models for medical training. According to the university, CRAFT could be used to create models that incorporate materials resembling bone, ligament and muscle within a single continuous structure.

The release notes that medical schools often rely on human cadavers for training, which can be expensive and difficult to obtain. Existing 3D-printed alternatives typically require costly inkjet printers and multiple materials that do not always bond well, sometimes leading to failures at material interfaces.

The researchers said models produced with CRAFT avoid these interface issues, resulting in structures that more closely mimic natural tissue transitions.

The team also pointed to possible uses in energy damping applications, such as soundproofing or personal protective equipment including helmets or armor. Page said the method could support the development of “bioinspired materials” with alternating hard and soft internal regions, similar to those found in natural systems like bone or tree bark, which can absorb impacts and vibrations without fracturing.

Page noted that he has previously worked on 3D printing methods that allow spatial control of stiffness and strength, but those approaches relied on more complex resin systems and custom-built equipment. In contrast, CRAFT is designed to work with some of the least expensive commercial 3D printers available.

Page said printers capable of grayscale projection can be purchased for around $1,000, lowering the barrier to adoption for researchers and institutions.

The researchers also addressed potential environmental considerations. While objects made using CRAFT are not fully recyclable, Page said they may still reduce waste because they can be melted down or dissolved using solvents and then recast into new shapes.

Funding for the research was provided by the US Department of Energy, the National Science Foundation and the Robert A. Welch Foundation.

The work was led by Alex Commisso and Samuel Leguizamon, both formerly with Sandia National Laboratories. Leguizamon is now a scientist at Savannah River National Laboratory, while Commisso is a materials chemist at Azul 3D.