Global defence tech giant Northrop Grumman has opened its new Hypersonics Capability Centre (HCC) in Maryland, US, to manufacture advanced propulsion solutions that can power hypersonic missiles beyond Mach 5.

Located in Elkton, the new HCC facility establishes the infrastructure and capacity required to enable the cost-effective mass production of hypersonic propulsion to support the US Defence’s growing demands for long-range, rapid-response weapons.

The facility is the first one in the United States specifically dedicated to the large-scale manufacturing of air-breathing propulsion, which includes ramjet and scramjet propulsion.

“This is a pivotal moment for hypersonics weapons; we have moved beyond building and demonstrating propulsion prototypes to large-scale manufacturing. Our proactive investment in this facility establishes the supply chain and optimizes manufacturing processes to produce hypersonic systems affordably at scale,” said Jim Kalberer, vice president for missile products at Northrop Grumman.

The HCC will support the US Air Force’s Hypersonic Attack Cruise Missile development and production and has the capacity to support future hypersonic systems work from across the US Department of Defence.

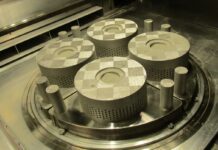

Northrop said the facility is equipped with cutting-edge production technology to implement digital engineering and consolidate engine manufacturing processes.

“Having Northrop Grumman expand its footprint in Maryland is a testament to our state’s thriving aerospace and defense industry. With the addition of this new facility, Cecil County is gaining a first-of-its-kind manufacturing center, as well as a significant number of new jobs. We are incredibly grateful to Northrop Grumman for its continued investment in Maryland,” said Kevin Anderson, commerce secretary for Maryland.

The HCC is Northrop’s latest manufacturing infrastructure expansion to boost weapons capacity for the US military and allies.

The facility will leverage metal manufacturing processes and precision non-destructive technologies to rapidly produce complex assemblies.