Aerospace composite manufacturer Quickstep has collaborated with the Sovereign Manufacturing Automation for Composites CRC (SoMAC CRC) and Deakin University’s Institute for Intelligent Systems Research and Innovation to help address the high cost of large-scale composite production.

Advanced industries like the aerospace and clean technology sectors are increasingly turning to ‘go-to’ solutions such as carbon fibre and other composites. Quickstep seeks to make the production system more cost-effective and enable a broader application of composite technologies, the company said in an ASX announcement.

The collaboration will leverage 3D photorealistic digital design, complex artificial intelligence-drive simulations, and new robotic design principles to mature new manufacturing technologies for cutting-edge airframe design and more cost-effective manufacturing system performance.

Quickstep will lead the project from its Geelong facilities, which are located on Deakin’s Waurn Ponds Campus continuing the long-standing collaboration.

The project’s 12-month program is valued at $1 million, funded 50-50, and forms part of an anticipated multi-year development program.

The collaboration is also part of Quickstep’s efforts to develop its advanced capabilities further and help make its Australian manufacturing operations even more competitive.

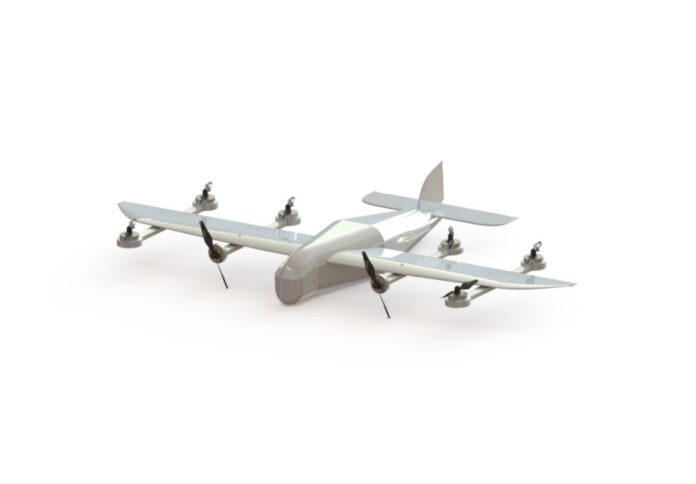

Aeroline is focused on high-rate low-cost production of complex aerostructures, including complete airframes. This builds on the recent automation program developed by Quickstep for the production of F-35 flares for the US Department of Defence and will support future automation and productivity at the company’s Bankstown site, as well as the existing Aeroline phase one setup used in drone programs in the company’s Geelong facility.