Scientists at the University of Sydney have developed a new method to produce ammonia using human-made lightning, potentially transforming the way one of the world’s most important chemicals is manufactured.

The breakthrough involves generating ammonia in its gaseous form using a combination of plasma and electrolysis, a simpler and potentially more sustainable alternative to the century-old Haber-Bosch process.

Currently, around 90 per cent of global ammonia production relies on the Haber-Bosch method, which is highly energy-intensive and reliant on fossil fuels.

“Industry’s appetite for ammonia is only growing,” said Professor PJ Cullen from the University of Sydney’s School of Chemical and Biomolecular Engineering and the Net Zero Institute.

“For the past decade, the global scientific community, including our lab, wants to uncover a more sustainable way to produce ammonia that doesn’t rely on fossil fuels.”

In a news release by the university, it states that ammonia plays a crucial role in global food production, as the main component in fertilisers that support nearly half of the world’s crops.

It also shows growing potential as a carbon-free fuel and as a hydrogen carrier, especially in hard-to-abate sectors like shipping, which accounts for about 3 percent of global greenhouse gas emissions.

In contrast to earlier methods that produced ammonia in solution form (ammonium, NH4+), requiring additional energy and steps to convert it into usable gas, the University of Sydney team’s technique directly generates ammonia gas.

This is achieved by exciting nitrogen and oxygen molecules in air using electricity, then converting them in a membrane-based electrolyser.

“In this research we’ve successfully developed a method that allows air to be converted to ammonia in its gaseous form using electricity. A huge step towards our goals,” said Professor Cullen.

“Currently, generating ammonia requires centralised production and long-distance transportation of the product. We need a low-cost, decentralised and scalable ‘green ammonia’.”

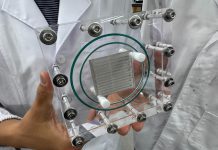

The process begins with a plasma generator that electrifies the air, exciting the nitrogen and oxygen molecules. These excited molecules are then fed into the electrolyser – a compact silver box – where they are converted into ammonia gas.

“This new approach is a two-step process, namely combining plasma and electrolysis,” Professor Cullen explained.

“We have already made the plasma component viable in terms of energy efficiency and scalability. To create a more complete solution to a sustainable ammonia production, we need to push the energy efficiency of the electrolyser component.”

The research was published in AngewandteChemie International edition.