Tag: Additive Manufacturing

Velo3D, US Army sign deal to develop 3D-printed parts for military supply chains

Velo3D has entered into a Cooperative Research and Development Agreement with the US Army’s DEVCOM Ground Vehicle Systems Center to develop and qualify additively manufactured metal parts aimed at addressing supply chain challenges affecting ground combat vehicles and other military systems.

Additive manufacturing by 3D People used in maritime sustainability project

Manufacturing expertise from London-based additive manufacturer 3D People has been used to produce a critical component for a maritime efficiency system trialled on a liquefied natural gas carrier.

Manufacturing firm 3D People urges industry to move beyond ‘price per part’ in additive...

London-based additive manufacturing specialist 3D People is calling on manufacturers to rethink how they evaluate 3D printing, emphasising in a new insight piece that an exclusive focus on “price per part” risks overlooking the broader value additive manufacturing brings to modern production.

DesignLab.au launch marks collaboration between global design and local manufacturing

Precision Plastics Australia has unveiled DesignLab.au, a new platform designed to link global product designers with Australian additive manufacturing capability, in a move that reflects the growing shift toward locally produced, design-led consumer goods.

Apple advances manufacturing with large-scale 3D-printed titanium components for Apple Watch

Apple says it has reached a major manufacturing milestone, announcing that all Apple Watch Ultra 3 and titanium Apple Watch Series 11 cases produced this year are made using 3D-printed enclosures created from 100 per cent recycled aerospace-grade titanium powder.

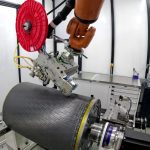

Manufacturing innovation drives Canberra firm’s development of advanced space composites

Canberra-based advanced manufacturing company New Frontier Technologies (NFT) is progressing a series of high-performance composite projects for the space sector, according to a joint media release.

New research centre to drive Australia’s additive manufacturing growth

Australia’s Additive Manufacturing Cooperative Research Centre (AMCRC) has been officially launched in Melbourne, marking what organisers described as a significant step toward enhancing the nation’s advanced manufacturing capabilities.

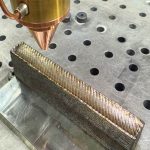

South Africa’s CSIR develops nano-reinforced polymer composite for advanced industries

The Council for Scientific and Industrial Research (CSIR), in collaboration with Filament Factory, has unveiled a nano-reinforced polymer composite designed to deliver new levels of performance in advanced materials.

RMIT researchers develop new 3D-printed titanium alloy

Engineers at RMIT University have developed a new type of 3D-printed titanium alloy that is approximately 29 per cent cheaper to produce than commonly used titanium alloys, marking what researchers describe as a significant advancement in additive manufacturing.

Amaero to supply Velo3D with certified metal powders for aerospace projects

Amaero Ltd has announced a new technical development collaboration with Auburn University’s National Centre for Additive Manufacturing Excellence (NCAME), marking a key milestone in the company’s expansion into advanced metal additive manufacturing.