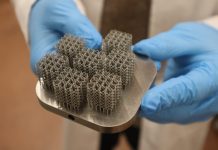

A team of scientists from the University of New South Wales has devised a way to 3D print bone-like structures complete with living cells, thus heralding a potential application of additive manufacturing in bone tissue repair.

In a study entitled ‘Synthetic Bone-Like Structures Through Omnidirectional Ceramic Bioprinting in Cell Suspensions’ published in Advanced Functional Materials, the authors developed a ceramic-based ink that opens the doors for use in the repair of damaged bone tissue.

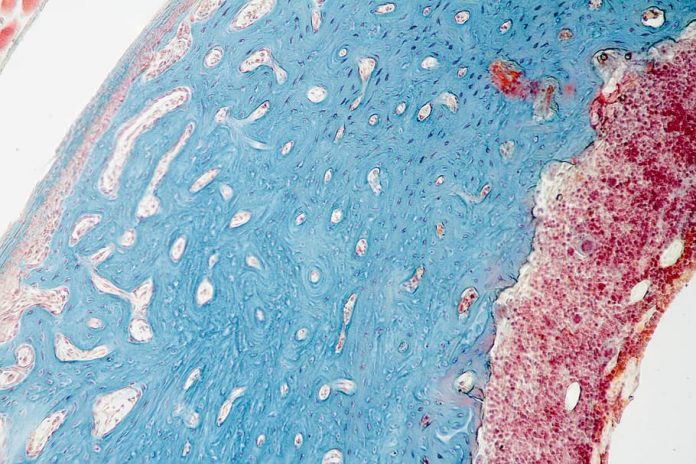

Despite recent studies in the field of 3D printing bone structures, replicating the actual conditions and properties of the bone environment is still a major hurdle among scientists.

This latest study creates bone-mimicking structures at room temperature, complete with living cells, and without invasive chemical or radiation – all factors that promote osteogenesis or bone formation.

Inspired by the naturally-occurring bone formation process, the scientists developed a technique known as ‘ceramic omnidirectional bioprinting in cell-suspensions’ (COBICS) that enables them to 3D print bone-like structures with a ceramic-based ink.

“This is a unique technology that can produce structures that closely mimic bone tissue,” said Dr Imam Roohani from UNSW’s School of Chemistry.

“It could be used in clinical applications where there is a large demand for in situ repair of bone defects such as those caused by trauma, cancer, or where a big chunk of tissue is resected.”