Stratasys Asia Pacific, a subsidiary of Stratasys Ltd — a global leader of 3D printing and additive manufacturing solutions, has announced that Western Tool & Mold (WTM) has purchased a second Fortus 3D Production System.

WTM is a Hong Kong based company that supplies total plastic solutions to aerospace, medical, electronic, industrial and speciality industries.

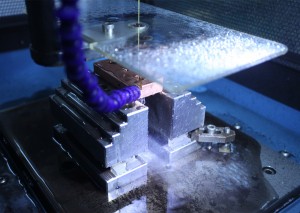

The company bought its first Stratasys Fortus 400mc Production System three years ago to make parts for aircraft interiors; with the second Fortus 3D Production System, WTM aims to reduce production time and cost, while improving resource management with “accurate and durable end parts for the aerospace industry.”

“Manufacturing process, particularly in the aerospace industry, is an ongoing challenge. Aircrafts placed on an assembly line need parts instantly. Receiving the parts on time is critical as penalties are placed if deadlines are missed. Stratasys 3D printing technology saves time, giving us the power to produce parts to quickly provide solutions to our customers’ problems, meeting immediate needs with accurate and durable end parts,” Collin Wilkerson, Managing Director of Western Tool & Mold said in a media release.

“Costs saved by customers could be used for tooling. 3D printing is not cutting income from our tooling and injection moulding business. Rather, it enables us to become a better supplier to our customers.”

The company is pleased with the results of integrating Stratasys 3D printing technology into the scope of service to customers, with 100% customers returning to manufacture additional parts, using the Fused Deposition (FDM) Fortus 400mc Production System; that is why, WTM has decided to purchase the second Fortus 3D Production System.

Most of the WTM manufactured parts are made with Stratasys ULTEM 9085, a Fused Deposition Moulding (FDM) thermoplastic that complies with applicable government regulatory requirements for the aerospace industry. ULTEM 9085 is a strong, lightweight material that is heat resistant, flame-retardant and offers full FST (flame, smoke and toxicity) — making it ideal for aerospace applications.