Eight researchers from the ETH Zurich University together with industry partners including contractor Erne AG Holzbau are building a three-storey DFAB House in the School’s campus that will be used to test smart home technologies.

The house, which is said to be the first house to be designed and planned primarily digital processes, is being built using digital fabrication methods and with the use of robots and large-scale 3D printers.

The pilot project is part of the National Centre of Competence in Research (NCCR) Digital Fabrication Project and is expected to help scientists determine how digital technologies can make construction more sustainable and efficient, and increase the design potential.

Professor Matthias Kohler said many of the techniques used to build the house have never been tested outside a lab.

“Unlike construction projects that use only a single digital building technology, such as 3D printed houses, the DFAB HOUSE brings a range of new digital building technologies together,” Professor Kohler said.

“This allows us to use the advantages of each individual method as well as their synergies, and express them architecturally.”

As part of the project, four construction methods are for the first time being transferred from research to architectural applications.

According to the press release by ETH, construction work began with the Mesh Mould technology, which received the Swiss Technology Award at the end of 2016 and is tipped to fundamentally alter future construction with concrete.

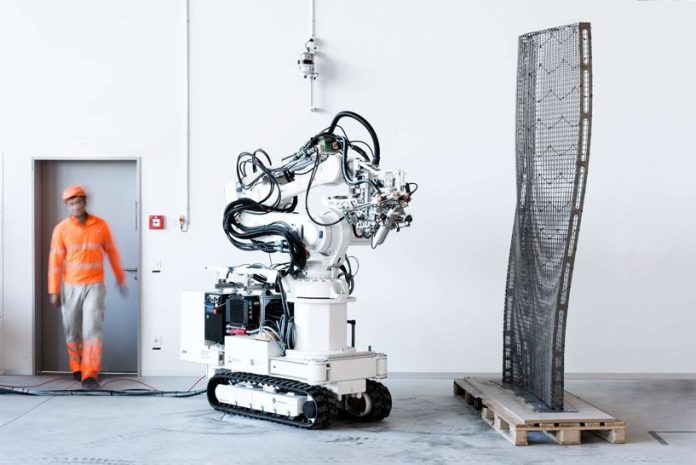

“Here, the two metre high construction robot In situ Fabricator plays a central role; it moves autonomously on caterpillar tracks even in a constantly changing environment. A steel wire mash fabricated by the robot serves both as formwork and as reinforcement for the concrete. Thanks to the dense structure of the steel wire mash and the special composition of the concrete mix, the concrete stays inside the grid and does not pour out,” reads the press release.

“The result is a double-curved, load bearing wall that will characterise the architecture of the open-plan living and working area on the ground floor. A Smart Slab will then be installed – a statistically optimised and functionally integrated ceiling slab, the formwork of which was manufactured using a large-scale 3D sand printer.”

The façade on the ground floor is being produced with the so called Smart Dynamic Casting technology, where complex structural elements can be constructed without the need for concrete moulds.

The two upper floors of the 200m2 building are being prefabricated at ETH Zurich’s Robotic Fabrication laboratory using Spatial Timber Assemblies, with cooperating robots to assemble the timber construction elements.

Professor Kohler pointed out that the fact that these technologies have so quickly found their way to the construction site was the result of both intensive collaboration between the different scientific disciplines and successful partnerships between research and industry.

“We are convinced that this collaboration is worthwhile for both sides,” he continued.

“An increasing number of Swiss companies, such as Erne AG Holzbau, which is the general contractor for the DFAB House and was previously involved in building the Arch_Tec_Lab at ETH Zurich, want to proactively use the opportunities of digital technologies – something that gives us great pleasure.”

The DFAB House will be completed in mid 2018.