The series is presented by

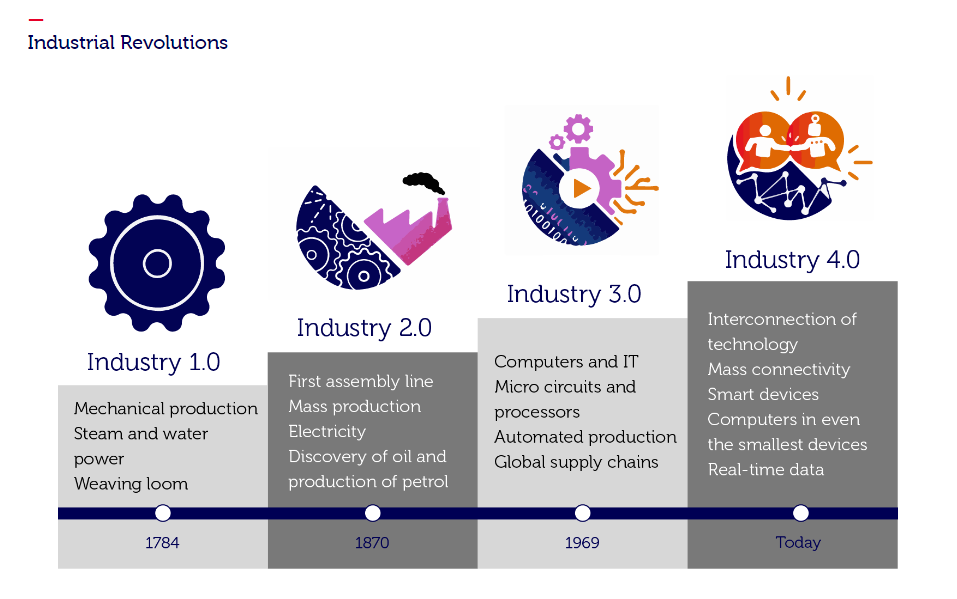

Cyclical change occurs in industry when novel and innovative technologies and methodologies start to transform and disrupt existing industrial practices. The fourth industrial revolution, or Industry 4.0 in common parlance is one such cyclical change that we are current in the midst of. It can be loosely defined as the introduction of automation and data exchange to create self governing manufacturing systems illustrated below.

There are several technologies and methodologies that define this change of paradigm. It is also interesting to see the changes in behaviour effected by this paradigm shift. Consumers are no longer loyal to brands and implied longevity, focusing instead on innovation. This, in turn, drives iterative rather than linear project cycles to mitigate the high rate of change brought about by this innovative focus. While we’ve explored the functional advantages and utility of 3D printing, there are less tangible advantages to be incurred by incorporating this technology which helps companies to effectively address this change in attitudes. This part of the series therefore explores how 3D printing can act as a competitive advantage rather than just an operational tool.

3D Printing as a cornerstone of Industry 4.0

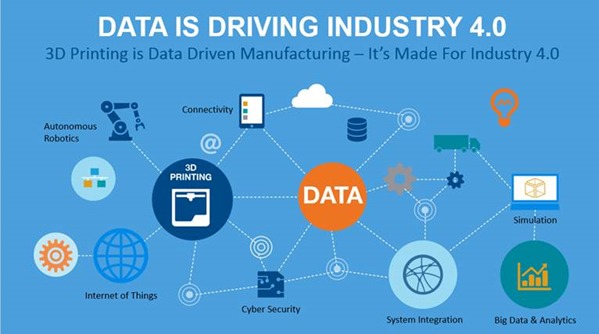

3D printing can be seen as one of the cornerstone technologies defining the fourth industrial revolution and integrates all the other technologies as seen below.

The speed of production of printers range from a few minutes to several hours, a vast difference from the week or month long novel production cycles of traditional manufacturing. This capacity for rapidity influences and matches the rapidly changing consumer expectations. The demand for customization and flexibility is also matched by the sophistication and precision of 3D printing. This is further enhanced by the CAD interfaces of 3D printers which enhance the design possibilities and innovative capabilities of any manufacturing process. Finally, the automation trend of Industry 4.0 is handled by the sophisticated production methodologies of 3D printers which reduces the need for multiple manufacturing processes.

Competition in Industry 4.0

Prior to discussing the competitive advantage of 3D printers, it is essential to understand the new competitive environment of Industry 4.0. Where large brands and consolidation once dominated markets, particularly in manufacturing, Industry 4.0 is characterized by many small, agile and flexible companies competing for lucrative contracts as noted by Antunnes et al (2018).3 The perceived ability of these smaller companies to alter and innovate quickly ties in with the shift towards innovation and functional optimization over loyalty and perceived reliability. Business relationships have also changed and the new environment is defined by partnerships and collaboration. This means that companies need to have compatible and integrated systems and projects are often planned across several organizations and departments with varying core competencies. Nonetheless, the quality of production is not expected to be compromised while balancing the changes and cost optimization.

Where 3D is a value proposition and competitive advantage

There are three main ways in which 3D printing can act as a competitive advantage given the altered business environment and these are as follow;

- Prototyping Speed

The speed at which 3D printing is able to produce prototypes is a massive competitive advantage in the altered business landscape. Faster production cycles lead to a marked ability to produce new market ready products. Since novelty is a major value proposition, the first mover advantage in most consumer markets is an important determinant of sales and profitability as noted by Jimenez et al. (2019).4 - Physical Prototypes

The product of 3D printing, as its name implies, is always a physical specimen. When coupled with the speed of the technology, there are several advantages to be accrued. Error correction and iterative redesign is sped up by the fact that a physical prototype can display both aesthetics and functionality simultaneously. Viable demonstrability is another property of 3 dimensional prototype which accelerates acceptance of design and creates greater excitement about sales. Finally, a physical prototype speeds up approval cycles as the prototype can readily be passed to various stakeholders to examine and opine on. RMIT’s Advanced Manufacturing Precinct’s director Professor Brandt noted that companies which used RMIT’s 3D printers often discovered defects as soon as protoypes were prepared thus reducing the troubleshooting cycle for new products. - Market Testing

Market testing is often the most critical part of the product cycle. Having too long of a market testing phase can be detrimental to the ability to start selling. 3D printing speeds up the market testing phase. Given the material adaptability of modern 3D printers, prototypes can be generated in the actual final product material with requisite form and function. As such, the prototypes are extremely close to the final product while being cost efficient. As such, the feedback on the product is immediate and relevant. This also reduces the expenses associated with the viable prototyping stage.

Hardware to gain Competitive Software

To achieve the competitive advantage garnered by 3D printing, the hardware has to exhibit a high level of sophistication and precision while integrating seamlessly into the existing working environment. Not all table top 3D printers are able to match these exacting requirements and offer up this industrial advantage. Industrial design 3D printers however, are able to produce detailed prototypes with various options for the material inputs. The Stratasys F123 series is a series of industrial design printers specifically engineered to integrate into office and existing infrastructure. The printers are designed to read data directly from CAD software via a plug and play interface thus eliminating the need for spec/ialized technical expertise. Stratasys was also one of the pioneers of 3D printing having created the Fused Deposition Method that produces the most precise 3D printed prototypes and remains a trusted name in 3D printing. To find out more about 3D printing as a competitive advantage and the F123 series, refer to the link below to sign up for a webinar.

What is Industrial Grade 3D Printing?

1 RMIT University, “What is Industry 4.0?”, 2019, https://www.rmit.edu.au/industry/develop-your-workforce/tailored-workforce-solutions/c4de/industry-40, 24/9/20192 The Manufacturer, 2016, “Where does 3D printing lie within Industry 4.0”https://www.themanufacturer.com/articles/where-does-3d-printing-lie-within-industry-4-0/, 24/09/2019

3 Antunes, Joaquim & Pinto, António & Reis, Pedro & Henriques, Carla. (2018). Industry 4.0: a challenge of competition. Millenium – Journal of Education, Technologies, and Health. 89-97. 10.29352/mill0206.08.00159.

4 Mariano Jiménez, Luis Romero, Iris A. Domínguez, María del Mar Espinosa, and Manuel Domínguez, “Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects,” Complexity, vol. 2019, Article ID 9656938, 30 pages, 2019. https://doi.org/10.1155/2019/9656938.