Australian semiconductor developer BluGlass Limited rolled out the first suite of its commercial gallium nitride (GaN) laser products for customer purchase at Photonics West in San Francisco in January, according to the company’s latest quarter activities update.

In the ASX announcement, the company said it is now offering its lasers across the violet 405nm, 420nm, and blue 450nm wavelengths in both single-mode and multi-mode devices, and in a range of flexible form factors, including TO Cans and Chip-on-Submounts.

Further laser products are underway, according to the company, spanning violet, blue, and green wavelengths in both single-mode and multi-mode devices. These include higher-power versions of launched products, as well as initial products in the 470nm, 488nm, and 525nm wavelengths.

During the latest period, BluGlass also secured multiple initial customer orders spanning its GaN latest product suite and in flexible form factors.

“Our first customers are established industry players, reflecting the growing need for alternative GaN laser suppliers, the quality of our first products, and BluGlass’ reputation as an upcoming innovator in the market. We have commenced shipments of these initial orders, and our lasers are already being tested within customer applications,” BluGlass CEO James Haden.

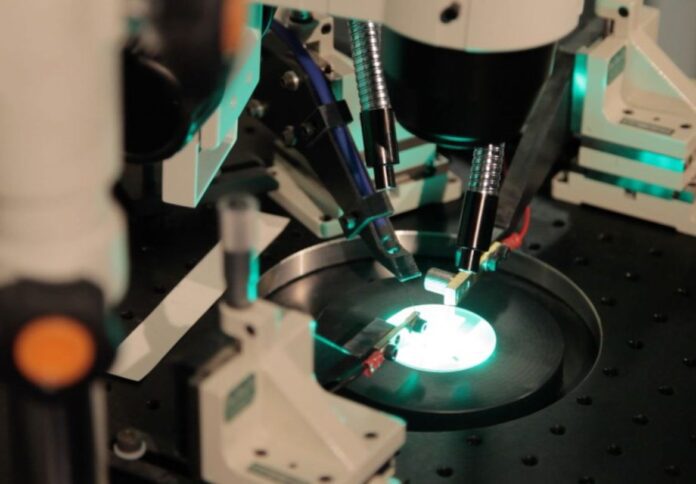

The ASX-listed company also provided updates regarding the vertical integration of its core wafer manufacturing processes into its Fremont fab.

P-side processing has been successfully vertically integrated and internal facet coating demonstrated with electrical and light-output performance in-line or better than contract manufacturer performance benchmarks, BluGlass said.

“With our own production facilities, we will soon have end-to-end operational capability of the GaN laser manufacturing process, from epitaxy to packaging and reliability testing. Our highly skilled manufacturing teams are leveraging these in-house capabilities to fast-track learning cycles, drive performance improvements and accelerate development of next-generation products,” Haden said.

“End-to-end manufacturing also enables us to effectively partner with customers to solve their biggest challenges, delivering enhanced performance, greater packaging flexibility and custom laser production.”

Appointed as the company’s CEO on 1 March, Haden said BluGlass remains focused on expanding its customer base and securing larger, recurring orders of its GaN lasers.

“This increased demand for visible GaN lasers is underpinned by many advantages over traditional infrared lasers, including higher absorption in key industrial metals, cleaner and faster materials processing, and tighter beam focus for precision manufacturing,” Haden said.