The Centre for Ocular Research & Education (CORE), a research facility that is part of the School of Optometry & Vision Science at the University of Waterloo, said it is preparing to reveal several advances in 3D printing at the upcoming Association for Research in Vision and Ophthalmology (ARVO) 2023 Annual Meeting in New Orleans next week.

During the event, slated to take place from 23 to 27 April, the institution will introduce breakthroughs that have broad implications and have the potential to speed up the development of drug delivery systems, biodegradable contact lenses, and pharmaceuticals.

The centre said a total of three related works focus on a new, CORE-developed method to rapidly fabricate PDMS (polydimethyl siloxane) microfluidic chips at a low cost and with high throughput.

These chips are used to examine the biological reactions of the eye to diverse environments, substances, and formulations.

“Our multidisciplinary team has created one of the most sophisticated 3D printing environments for ocular research in the world,” said Alex Hui, OD, PhD, FAAO, head of Biosciences at CORE.

Hui continued, “This investment in people and technologies is opening doors for new discoveries, product validation, and clinical insights, with so many implications for enhancing vision.”

In particular, human corneal epithelial cells (HCECs) were specifically included by the researchers, and these cells demonstrated significant adhesion, metabolic activity, and growth potential, demonstrating the viability of chip-based cell biology studies.

Additionally, CORE created a PDMS microfluidic device for testing medication release from contact lenses.

Meanwhile, ARVO organisers have designated “Fabrication of a Microfluidic Chip for Ophthalmic Drug Delivery Studies Using 3D Printing” (Ramasamy M., et al.) as a scientific highlight for the entire conference.

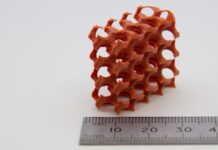

Another CORE program that will be presented in New Orleans created a biodegradable bio-ink for the fabrication of ophthalmic equipment.

A novel gelatin methacrylate (GelMA)-centric formulation was used with a commercial masked-stereolithography (mSLA) 3D printer, with the resulting material assessed for degradation.

The researchers additionally manufactured a contact lens out of the same material, without the use of any support structures during the printing process, according to CORE.

For more information about the upcoming event, visit this site.