Researchers at the University of Houston have developed a new class of ceramic structures capable of bending under pressure without breaking, potentially opening the door for their use in applications ranging from medical prosthetics to aerospace components.

The research team, led by Maksud Rahman, assistant professor of mechanical and aerospace engineering, and Md Shajedul Hoque Thakur, a postdoctoral fellow, has drawn inspiration from origami to reimagine how ceramics behave under stress.

Their findings were recently published in Advanced Composites and Hybrid Materials.

Ceramics are valued for being lightweight, durable, and biocompatible, but their brittleness has long limited their use in environments where materials must endure repeated or intense mechanical stress.

“Ceramics are incredibly useful — biocompatible, lightweight and durable in the right conditions — but they fail catastrophically,” said Rahman in a statement.

“Our goal was to engineer that failure into something more graceful and safer.”

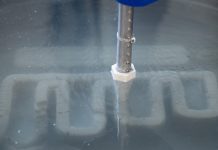

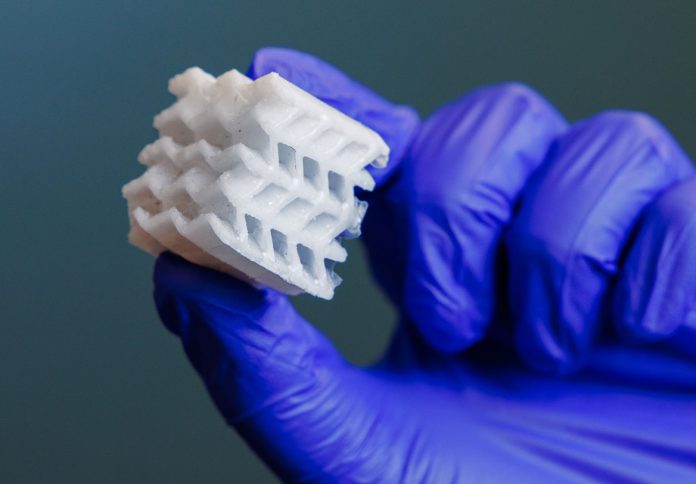

To address this, the researchers 3D printed ceramic structures using the Miura-ori pattern – a folding technique traditionally used in paper origami to allow flat surfaces to collapse and expand efficiently.

The team then coated the ceramic forms with a stretchable, biocompatible polymer that helped prevent them from cracking under pressure.

In a series of laboratory tests, both static and repeated compression trials showed that the polymer-coated ceramics could flex and recover without breaking, unlike uncoated versions, which typically cracked or shattered under the same conditions.

Computer simulations supported the experimental results, revealing that the coated structures had significantly improved toughness, especially in directions where traditional ceramics are weakest.

The University of Houston researchers believe the innovation could make ceramics viable in new fields that require lightweight but resilient materials, such as robotics, aerospace, and biomedical engineering.

While further testing and development are needed before commercial adoption, the study represents a significant step in adapting traditionally brittle materials for flexible, real-world use.