Digital twin modelling is reshaping how infrastructure and manufacturing systems are designed, operated, and maintained, according to researchers at the University of New South Wales (UNSW).

Unlike static simulations, digital twins are dynamic, data-driven replicas of physical assets – from machines to buildings to biological systems – that continuously update in real-time based on sensor feedback.

UNSW reported that this technology enables engineers to track performance, detect potential issues before they arise, and manage maintenance with greater accuracy.

“A digital twin doesn’t just simulate, it lives with the machine,” said Associate Professor Pietro Borghesani from UNSW’s School of Mechanical and Manufacturing Engineering. “You can use the digital history of your machine to control how the asset degradation is evolving and then use that knowledge to streamline your operations.”

Data reported showed that digital twins are already gaining traction in manufacturing, with about 29 per cent of global manufacturers reportedly implementing digital twin strategies.

Borghesani said the real-time insights offered by digital twins make them particularly valuable in industries where safety and cost-efficiency are paramount. “Instead of being reactive to what happens to the asset, it allows us to plan – but with better accuracy,” he noted.

UNSW reports that although digital twins were initially applied to complex systems like wind turbines and industrial machinery, the technology is now being investigated for use in fields such as construction and healthcare.

In the medical sector, researchers are exploring the use of digital twins of human organs to model disease progression and tailor treatment approaches.

“The same principles apply: feed in patient-specific data, update the model continuously, and simulate future outcomes,” Borghesani said. “The only thing that changes is the physics.”

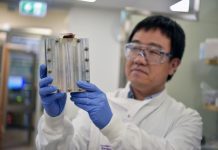

Data is the foundation of every digital twin, but it’s not the only ingredient. Professor Zhongxiao Peng, head of UNSW’s Tribology and Machine Condition Monitoring Research Group, said that in many high-stakes environments, quality data is often scarce.

“In many critical applications, it is often difficult to collect large amounts of data, especially under different operating or faulty conditions,” Peng said. “For example, if you are using a digital twin to predict wind turbine failures, you don’t want a lot of data because that would mean that many wind turbines have failed – which I know is a little contradictory.”

To address these limitations, Peng said engineers build models based on physical principles, supplementing them with available data to fine-tune their accuracy.

According to UNSW, digital twins offer more than just asset monitoring, also serving as digital repositories of engineering knowledge.

Borghesani said companies can embed expert knowledge into their twins, providing continuity even when experienced staff leave.

“This is especially appealing for medium-sized firms, which often struggle to recruit or retain highly specialised staff,” he said. “A well-designed digital twin acts as both a performance monitor and a training tool for the next generation of engineers.”

As digital twins scale from machines to larger systems, such as transport networks or energy grids, researchers are exploring alternative ways of collecting live performance data. Borghesani cited “crowd sensing” as a potential solution, using data from routine activities like driving to monitor infrastructure.

“Imagine you could help collect data on road infrastructure just by driving your normal route to work,” he said. “There have been studies that have done just that, with multiple vehicles collecting data to estimate road roughness.”

He acknowledged that privacy concerns and data ownership issues remain a hurdle but suggested other sources, such as satellite imagery, could also support digital twin development.

While artificial intelligence (AI) is emerging as a powerful tool in automating digital twin creation, Borghesani cautioned that AI-driven models often lack transparency.

“With traditional models, you understand the physics and the reasoning because you start with the expertise,” he said. “With AI, it’s often a black box. It’s not expertise you’re putting into the software; it’s a lot of historical data.”

He said UNSW researchers are working on hybrid models that combine physics-based approaches with AI, aiming to leverage the strengths of both. “It’s about enhancing, not replacing, the expertise,” he said.

As technology continues to evolve, Borghesani said the role of digital twins in manufacturing and infrastructure will only grow.

“In the past, you may have only had a few dozen power plants to manage. But now you have thousands of wind turbines and millions of solar panels feeding into the same energy grid,” he said. “Whether it’s keeping a wind farm running smoothly, or infrastructure safe and efficient, digital twins are emerging as a key tool.”