Advanced Navigation has announced that it has demonstrated high-precision underground positioning without the use of fixed infrastructure or GNSS, achieving consistent results in Europe’s deepest underground mine in Pyhajarvi, Finland.

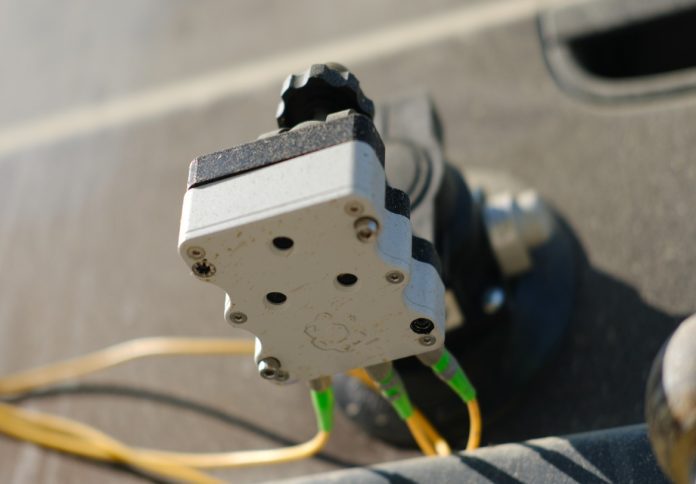

The company said its Hybrid Navigation System, which integrates a Laser Velocity Sensor (LVS) with the Boreas D90 fibre-optic gyroscope (FOG) Inertial Navigation System (INS), maintained sub-0.1 per cent navigation error across multiple test runs, without relying on pre-existing maps or external aids.

“Unreliable navigation underground isn’t a minor technical constraint – it’s a major operational bottleneck,” said Joe Vandecar, Senior Product Manager at Advanced Navigation.

“Maintaining precision over a 22.9 km subterranean course in Europe’s deepest underground mine demonstrates a level of performance that few systems in the world can rival without any prior intelligence of the environment. These results prove we’re one step closer to unlocking scalable underground autonomy.”

Located 1.4 km underground and just two degrees below the Arctic Circle, the Pyhäsalmi Mine presents significant navigation challenges, including the absence of GNSS signals, complex multi-level tunnels, and metallic ores that distort magnetic fields and scatter radio waves.

Mines often address these limitations with infrastructure-heavy solutions such as ultra-wideband beacons, Wi-Fi, or 5G repeaters, or with perception-based approaches like SLAM, which require cameras.

Advanced Navigation said its inertial-centred architecture offers a scalable alternative with less reliance on such infrastructure.

The Boreas FOG INS at the core of the system determines true north using gyrocompassing, while the LVS uses infrared lasers to measure true 3D velocity relative to the ground.

This data is processed by the company’s AdNav OS Fusion software, which adaptively weighs the reliability of each sensor in real time to maintain precision over extended distances.

Magnus Zetterberg, Senior Consultant at Combitech, who observed the demonstration, said, “We were thoroughly impressed by the results the sensor fusion provided. I have used and been exposed to these sorts of sensors in other projects, and nothing has come close to this level of performance. It’s clear the Laser Velocity Sensor is a major key in providing these outstanding results.”

The system was tested over five separate runs, achieving accuracy of better than 0.1% of distance travelled, including one test in which it navigated a 1 km course with only one metre of error after a true north-seeking initialisation 1.4 km underground.

Advanced Navigation said this performance surpassed standard single-band GNSS accuracy on the surface in open-sky conditions.

“At Normet, we specialise in advanced solutions for underground mining and tunnelling, so we know firsthand how difficult accurate and reliable navigation can be in these environments,” said Olli Mylläri, Vice President Technology at Normet.

“Seeing Advanced Navigation’s Hybrid Navigation System deliver consistent positioning with minimal infrastructure deep within the Pyhäsalmi Mine was remarkable. It’s a powerful step forward for automation and safety in the underground space.”

Advanced Navigation said the technology reduces dependency on fixed infrastructure and could enable more resilient navigation in inaccessible or unmapped areas, supporting applications such as fleet management, predictive collision avoidance, material tracking, and scalable autonomy in mining operations.

Vandecar added, “Ultimately, this vehicle-based, inertial-centred architecture provides the resilient foundation required for the mining sector to achieve its long-term goal: efficient autonomous ore extraction at depths hostile to human activity.”

The company expects to commercially release the Hybrid Navigation System in late 2025.