Global flooring manufacturer Milliken has launched Renasci, a new resilient flooring product designed to turn carpet and soft plastic waste into recyclable flooring planks, in a move the company says could reshape the industry’s approach to waste and manufacturing.

According to data reported by Milliken, carpet recycling has been a longstanding challenge in Australia and New Zealand, with around 90,000 tonnes of carpet waste and one million tonnes of soft plastics sent to landfill annually.

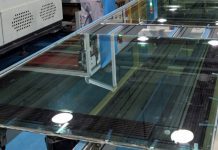

Milliken said Renasci addresses this issue by using a process that shreds whole carpet tiles and soft plastics such as shopping bags, pressing them into durable flooring planks without glues or chemical adhesives.

“With Renasci, we’re giving waste a second life and the industry a new path forward,” said Shaneel Deo, managing director at Milliken.

The company said the process not only diverts waste from landfill but also allows installation off-cuts and end-of-life products to be fed back into the system, creating a closed-loop recycling process.

Milliken developed the product in collaboration with saveBOARD, combining the latter’s expertise in material processing with Milliken’s experience in flooring design and manufacturing.

The result, according to the company, is a low-carbon alternative to conventional vinyl and hard flooring.

Renasci is part of Milliken’s N/XT LIFE Circularity Program, which underpins the company’s global sustainability commitments.

The product is being distributed through commercial flooring distributors across Australia and New Zealand.

Milliken, which has operated in the region for over 40 years, said its focus on manufacturing excellence and sustainable design continues to drive its innovation in the commercial flooring sector.