Perth-based seaweed materials company Uluu has announced it has raised $16 million in Series A funding to expand its manufacturing capability and build a demonstration plant in Western Australia, advancing its mission to produce a natural, seaweed-based alternative to conventional plastics.

In a statement, Uluu said the funding round was led by German growth investor Burda Principal Investments, with participation from Main Sequence, Novel Investments (the family office of one of the world’s largest textile groups), Startmate, and a consortium of leading impact and family investors including Fairground and Trinity Ventures.

According to Uluu, the investment will enable the company to scale from its 100kg-per-year pilot facility to a 10-tonne-per-year demonstration plant, positioning it to deliver commercial volumes of its materials to customers.

The company said its next-generation materials are designed to match the performance of conventional plastics while remaining reusable, recyclable, home compostable, and marine biodegradable.

Uluu noted that its materials can be processed using existing plastic manufacturing equipment, providing an avenue for rapid industrial integration.

“After four years’ work developing this technology, including two years running our pilot plant, we’re excited to take this next step and start delivering meaningful volumes of our materials to customers,” said Uluu co-founder and co-CEO Michael Kingsbury.

“The demonstration plant is a critical step in showing Uluu can scale to truly compete with and replace fossil plastics.”

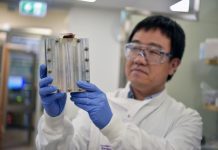

Uluu said its proprietary production process combines seaweed with fermentation to create natural polymers known as PHAs, removing dependence on fossil fuels and addressing persistent plastic pollution.

The company estimates that at commercial scale, the process could sequester and avoid up to 5kg of CO2 equivalent for every kilogram of material produced, compared with approximately 3kg emitted by conventional plastics.

“Seaweed grows quickly and gets everything it needs from the sun and the sea,” said Uluu co-founder and co-CEO Dr Julia Reisser.

“It locks away CO2 and helps clean up pollutants from the ocean. By harnessing seaweed, Uluu is producing materials that have a positive, rather than negative, impact on the environment, while ending plastic pollution.”

Uluu said it is already collaborating with several international brands in the cosmetics, fashion, and automotive industries, including public campaigns with Quiksilver, Papinelle, and Audi.

Among Uluu’s international investors is model, entrepreneur, and STEM education advocate Karlie Kloss, who said she was drawn to the company’s sustainability mission.

“Uluu is tackling one of the biggest challenges of our time – plastic pollution – with a natural, scalable solution,” Kloss said in a statement shared by Uluu.

“Their mission resonates deeply with me, and I wanted to be part of a positive change showing sustainability can be beautiful.”

Commenting on the investment, Burda Principal Investments CEO Christian Teichmann said the firm was pleased to continue supporting Uluu’s growth trajectory.

“Having first invested in Uluu in 2023, we’re excited to further deepen our partnership as the company scales its pioneering technology,” Teichmann said in the statement released by Uluu. “Uluu is redefining how materials can be produced more sustainably at industrial scale.”

Founded in 2021 and headquartered in Perth, Uluu said it has expanded its workforce from 13 to 23 employees this year, strengthening its technical, operations, and commercial teams.

The company added that it is planning a commercial-scale facility capable of producing thousands of tonnes annually to serve major global markets.

Uluu said it was recently recognised with the 2025 SXSW Innovation Award in Austin, Texas, for its advances in sustainable materials innovation.