The ASX-listed company said the achievement marks the completion of commissioning and the beginning of operational testing under concentrated solar conditions, progressing the company’s efforts to commercialise its photocatalytic water splitting (PWS) technology.

In a statement, the company said the transition to operational testing reinforces Sparc Hydrogen’s position in the emerging PWS field, which it described as a potential pathway to low-cost green hydrogen production in a sector projected to be worth USD 1.4 trillion annually by 2050.

Sparc Hydrogen is a joint venture between Sparc Technologies, MIH2 Pty Ltd – a wholly owned subsidiary of Fortescue Ltd – and the University of Adelaide, which has been developing its patented reactor technology since 2022.

Sparc Managing Director Nick O’Loughlin said the milestone reflects more than a year of work since the start of the FEED study.

“Sustained hydrogen generation at Roseworthy is a significant milestone for Sparc Hydrogen and the broader green hydrogen and photocatalytic water splitting industries,” he said.

“Successful commissioning of this first-of-its-kind plant is the culmination of over 12 months of hard work … and positions Sparc Hydrogen at the global forefront of this emerging direct solar-to-hydrogen technology.”

He added that the pilot plant demonstrates the potential of Sparc Hydrogen’s reactor system. “I congratulate the project team and our partners, Fortescue and the University of Adelaide, on this significant achievement and look forward to showcasing the pilot plant as an example of the simplicity and scalability of Sparc Hydrogen’s reactor technology and how it can potentially unlock low-cost green hydrogen.”

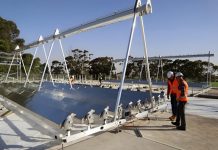

According to Sparc, the Roseworthy facility represents an important step toward scaling and commercialising its patented PWS reactor technology.

The company said the plant enables testing of different reactor designs and photocatalyst materials under real-world conditions, supporting laboratory validation and performance benchmarking.

Sparc said the R&D team will initially test reactors across a range of solar concentrations, temperature and pressure settings using photocatalyst materials from Shinshu University in Japan.

Sparc noted it is engaging with additional photocatalyst developers to facilitate further testing at the site.

The company expects the Roseworthy facility to become a “globally significant” hub for PWS research and commercialisation and said the pilot program aims to advance its technology from TRL-5 to TRL-6/7 through semi-continuous operation using commercially available concentrated solar mirrors.

As outlined in the media release, the pilot plant will also be used to demonstrate how the system performs under real-world conditions and to strengthen Sparc Hydrogen’s position as a partner for photocatalyst developers.

The company said the facility will help showcase its technology to stakeholders and funding bodies as development progresses.

Sparc highlighted several potential advantages of its PWS process, noting that the method removes reliance on renewable electricity and electrolysers, which can be significant cost drivers in green hydrogen production.

The company noted PWS uses sunlight and a photocatalyst to produce hydrogen directly from water, offering a simplified process with the potential for low production costs.

“Sparc Hydrogen’s pioneering technology employs a photocatalyst and sunlight to produce green hydrogen directly from water,” the company stated, adding that the approach delivers emissions-free hydrogen and industrial heat while using scalable concentrated solar infrastructure.

It also identified potential benefits for off-grid and remote applications due to reduced dependence on electricity supply.

The content of this article is based on information supplied by Sparc Technologies Limited. For more information, please refer to the official company announcement and communications from Sparc. Please consult a licensed and/or registered professional in this area before making any decisions based on the content of this article.