AM Solutions, a provider of post-processing technology for additive manufacturing and a brand of the Rösler Group, has launched a new compact M1 system, positioning it as a manufacturing-focused solution designed to support production-grade surface finishing of 3D-printed metal and polymer parts.

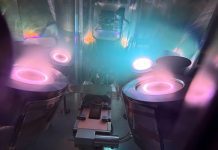

Announced on 11 February 2026 in Knowsley, United Kingdom, the new M1 replaces the earlier M1 Basic model and introduces a range of upgrades intended to improve flexibility, workflow and process stability for manufacturing environments.

AM Solutions said the system is aimed at users seeking consistent, repeatable finishing results that can be integrated into existing manufacturing processes.

“The first M1 Basic proved how powerful vibratory finishing can be for additive,” said Colin Spellacy, Head of UK Sales at AM Solutions.

“But our customers asked for more flexibility, better ergonomics, and even higher process stability. The new M1 is our answer. It turns what used to be an entry-level solution into an advanced production tool.”

According to the company, a divider system allows up to three process steps to run in parallel without changing media, supporting multi-stage finishing commonly required in manufacturing applications.

AM Solutions said key updates include an additional fresh-water connection compatible with its Keramo-Finish® process, a redesigned processing trough with added partitions, and a new separation concept that relocates media and part separation to a dedicated material cart to improve throughput.

Despite these additions, the company noted the system retains a compact, mobile footprint with plug-and-play installation.

“For many AM users, the real bottleneck isn’t printing, it’s finishing,” Spellacy said. “With the relaunched M1, we’re giving them a robust, repeatable and economically attractive way to turn rough builds into market-ready products, without jumping straight to a large, fully automated line.”

AM Solutions said the M1 launch strengthens its broader manufacturing-focused portfolio of scalable post-processing technologies, offering manufacturers a pathway from early-stage additive manufacturing trials to more industrialised production workflows.