Media Release

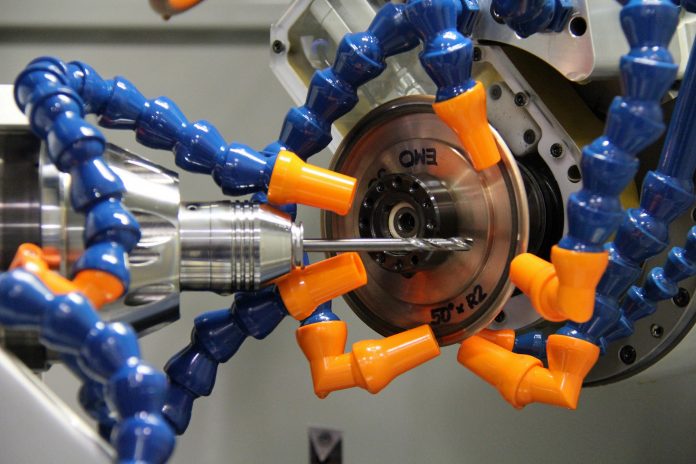

ANCA Australia is expanding its in-house manufacturing capabilities, developing a hybrid additive-subtractive manufacturing platform to manufacture Tungsten custom designed cutting tools.

It’s being developed alongside Australia’s national science agency, CSIRO, and Sutton Tools, and is supported with matched funding from the Advanced Manufacturing Growth Centre (AMGC).

Successful completion of the project will allow ANCA to commercialise the new hybrid additive manufacturing machine platform while growing its workforce, revenue and fulfilling a gap in the global tooling market, to which it already supplies Airbus, Boeing, Renishaw and Fraisa.

The project builds on previous research and development (R&D) between ANCA and CSIRO through a six-month pilot program funded by the Victorian Government’s Boost Your Business voucher scheme.

Together, ANCA and CSIRO have demonstrated that the Tungsten-carbide tools could be made cheaper through improved production efficiencies compared to traditional Tungsten products.

In 2015, ANCA began exploring the potential for additive manufacturing to disrupt the Tungsten cutting tool market, which is worth an estimated $2.2 billion globally.

Following significant research and the development culminating in a report with CSIRO, both parties entered a six-month pilot program.

Dean McBain, ANCA’s Research and Technology Manager said: “Such a complex project and process wouldn’t be possible without the support of trusted partners such as CSIRO, Sutton Tools and AMGC.

“We rely on working with organisations like CSIRO who have the laboratory, equipment and knowledge that we do not have. Sutton Tools are also hugely important as they provide practical input from the end-user perspective. Collaborating with others is vital and it makes sense to partner with organisations like them.

“Similarly, AMGC is pretty much the only organisation that can provide funding assistance for a business of our size, apart from the much larger CRC-type projects, which need to run for two to three years. In terms of balancing what is applicable, AMGC works out perfectly for us,” said McBain.

Managing Director of AMGC, Jens Goennemann said that ANCA’s successful pilot is a great example of collaboration and technology combining to solve a complex problem.

“ANCA’s project is a perfect example of how collaboration can find solutions to complex issues. In this instance the collaboration of two leading Australian companies and the country’s preeminent research institution to deliver an innovative solution to a multi-billion dollar global market”.

“Australia’s future prosperity lay in advanced manufacturing, in making complex things. It is the answer to many of the challenges that face us be it energy, efficiency, resources, productivity and value – what ANCA, CSIRO and Sutton Tools have developed is a better value product that uses less raw material, is more durable and is manufactured here – that a job well done,” said Goennemann.

CSIRO project leader, Dayalan Gunasegaram, says: “We’re looking forward to continuing to work with ANCA to refine and develop their additive manufacturing platform for new tungsten carbide tools, given the value that this could create for Australian manufacturing.”

Image Provided