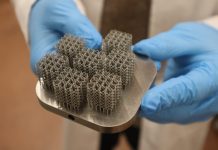

Apple says it has reached a major manufacturing milestone, announcing that all Apple Watch Ultra 3 and titanium Apple Watch Series 11 cases produced this year are made using 3D-printed enclosures created from 100 per cent recycled aerospace-grade titanium powder.

In a news release, the company said the shift marks the first time this approach has been achieved at scale for its products.

“It wasn’t just an idea — it was an idea that wanted to become a reality,” said Kate Bergeron, Apple’s vice president of Product Design. “We had to prove, with continuous prototyping, process optimisation, and a tremendous amount of data gathering, that this technology was capable of meeting the high standard of quality we demand.”

Apple said the new additive manufacturing process allows the watches to be produced with roughly half the raw material previously required. According to Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation, the reduction represents a significant step toward the company’s Apple 2030 goal to eliminate carbon emissions across its entire footprint.

“A 50 per cent drop is a massive achievement — you’re getting two watches out of the same amount of material used for one,” Chandler said. “When you start mapping that back, the savings to the planet are tremendous.”

The company estimates that more than 400 metric tons of raw titanium will be saved in 2025 through the new process.

Apple said the technology also enables improvements in durability, performance and component design, including new textures that were not possible with traditional forging.

Dr J Manjunathaiah, senior director of Manufacturing Design for Apple Watch and Vision, said the transition reflects long-running work to test 3D-printed metal for cosmetic parts.

“Using less material to make our products has always been the intention,” he said. “Previously, we hadn’t been able to make cosmetic parts at scale with 3D printing.”

Apple’s environmental and design teams said the project required advances in materials science, reliability testing and precision manufacturing, including tightly controlled powder composition and laser-based printing conducted over hundreds of layers. “This was cutting-edge materials science,” Bergeron said.

Chandler said the adoption of 3D printing is intended to create permanent, system-wide improvements. “We’re never doing something just to do it once — we’re doing it so it becomes the way the whole system then works,” she said. “When we come together to innovate without compromise across design, manufacturing, and our environmental goals, the benefits are exponentially greater.”

Apple added that the breakthrough has also enabled new manufacturing possibilities beyond Apple Watch, including the titanium USB-C port enclosure on the new iPhone Air, which uses the same recycled titanium powder and 3D-printing process.