Two Australian high-tech manufacturers have collaborated to develop an advanced inspection system, addressing a critical challenge in precision engineering and opening new commercial avenues.

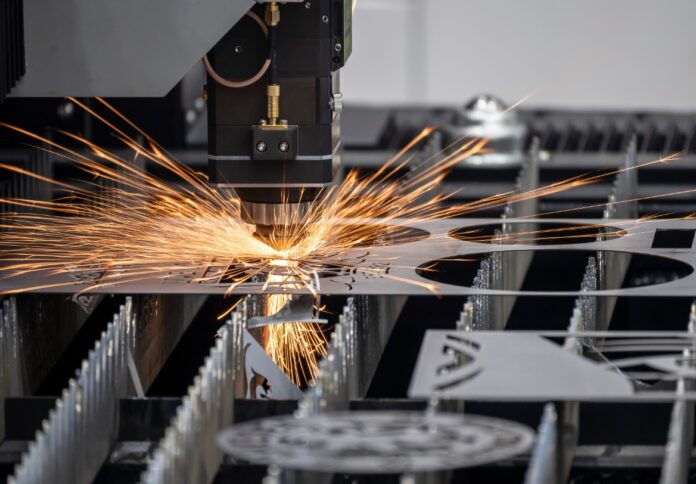

ActionLaser, a company established in 1988 as a spin-off from CSIRO, specialises in producing precision perforated screens used in industries such as plastic recycling, food and beverage, and water filtration.

With the support of the Advanced Manufacturing Growth Centre (AMGC), ActionLaser partnered with OptoTech, a Victorian-based firm specialising in laser-based inspection systems for semiconductor, medical device, and hard drive industries. Both companies export a significant portion of their products internationally.

David Pask, Production Manager at ActionLaser, highlighted the importance of precise quality control.

“We could previously measure perhaps 100 holes on a disc and extrapolate from there, but with around 500,000 holes per disc, we needed a more reliable method to meet international standards,” Pask said.

Through collaboration with OptoTech, ActionLaser has adopted an advanced inspection system capable of mapping each hole’s size and distribution, enabling the company to calculate the “flow through” of its filtration discs—a key performance metric.

This capability sets ActionLaser apart from competitors, as no other manufacturer currently offers such precise flow rate verification.

OptoTech Director Mircea Petre noted that creating a highly detailed map of a disc posed significant challenges due to the tiny size of the holes and the vast number of features involved.

“The disc inspection system we have developed with ActionLaser is not something you can just grab off the shelf, it is a highly complex product requiring a complex solution,” Petre said.

Dr Jens Goennemann, Managing Director at AMGC, underscored the broader significance of the collaboration: “Collaboration should be in every manufacturer’s toolbox.”

“There is a magic in finding the right experts and trusting them to deliver on something you couldn’t possibly do inhouse. Experts for a problem as complex as this one might take some legwork, but they’re out there and AMGC knows where they are.”

According to AMGC, the project is already yielding results. ActionLaser has reportedly increased production of its MeltFilters, scaling from 100 units annually to 1,500, with future projections reaching 5,000 units.

Pask attributes this growth to the new inspection technology, which allows the company to provide verifiable performance data to customers.

Beyond technological advancement, Pask sees the collaboration as a lesson in shifting from a traditionally insular approach to manufacturing toward a more open and cooperative model.

“So, networking events and making connections that way might not come to anything. That chat with OptoTech might’ve gone nowhere, but it was the right place, right time to do something.”

Since its inception, AMGC has facilitated over 500 national collaborations, co-funded more than 161 industry projects, and contributed to the creation of over 4,300 jobs.

With combined government and industry investment exceeding $137 million, these initiatives have generated an estimated $1.62 billion in additional national revenue.

For further details on AMGC membership and support programs, visit this site.