Researchers from CSIRO, Australia’s national science agency, in partnership with Wollongong-based Medical Innovation Hub, have come up with a way to 3D print tailor-made stents, a critical biomedical device used to treat narrow or blocked arteries.

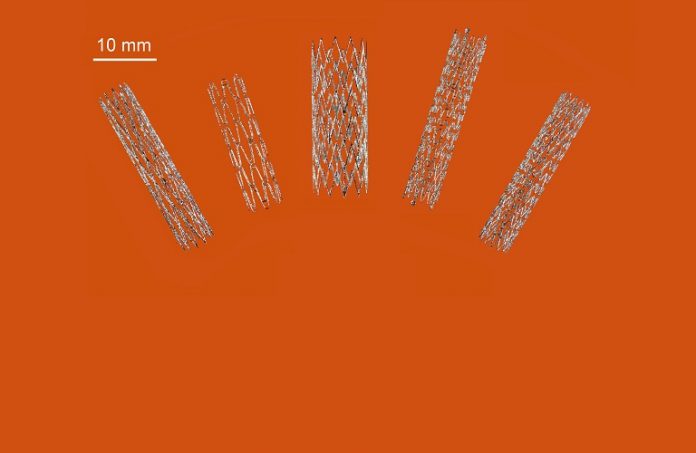

Using a cutting-edge 3D printing process called Selective Laser Melting, the team of scientists at CSIRO’s Lab22 in Melbourne were able to 3D print a self-expandable nitinol stent without compromising the metal’s unique properties.

The breakthrough means that surgeons will no longer be restricted to accessing ‘off-the-shelf’ stents for operations, allowing them to create complex products with high geometric accuracy that are patient specific.

Chief Executive of Medical Innovation Hub Dr Arthur Stanton said the breakthrough represents ‘a paradigm shift’ in the production of self-expanding nitinol stents for Peripheral Arterial Disease (PAD), which afflicts more than 10% of Australians.

“Currently, surgeons use off-the-shelf stents, and although they come in various shapes and sizes, overall there are limitations to the range of stents available,” Dr Stanton said.

“We believe our new 3D-printed self-expanding nitinol stents offer an improved patient experience through better fitting devices, better conformity to blood vessel and improved recovery times.

“There is also the opportunity for the technology to be used for mass production of stents, potentially at lower cost.”

CSIRO Principal Research Scientist Dr Sri Lathabai said the process could allow for individual stents to be made on-site, under the surgeon’s direction, with high geometric accuracy to suit individual patient requirements.

“Nitinol is a shape-memory alloy with superelastic properties,” Dr Lathabai continued.

“It’s a tricky alloy to work with in 3D printing conditions, due to its sensitivity to stress and heat.

“We had to select the right 3D-printing parameters to get the ultra-fine mesh structure needed for an endovascular stent, as well as carefully manage heat treatments so the finished product can expand as needed, once inside the body.”

Minister for Industry, Science and Technology, Karen Andrews, said the technology could revolutionise the $16 billion global stent manufacturing industry.

“This is a great example of industry working with our researchers to develop an innovative product that addresses a global need and builds on our sovereign capability,” Minister Andrews said.

A newly established company, Flex Memory Ventures, has been tasked with driving the commercialisation of the technology.

Image credit: https://www.csiro.au