Conflux Technology, a global leader in heat transfer and additive manufacturing (AM), has raised $11 million in a Series B funding round.

The investment, led by Breakthrough Victoria and joined by AM Ventures and Acorn Capital, is set to propel the company’s technological innovation and expand its support to customers worldwide.

Conflux Technology said it is redefining heat exchange capabilities to support industries’ efforts towards achieving net zero emissions.

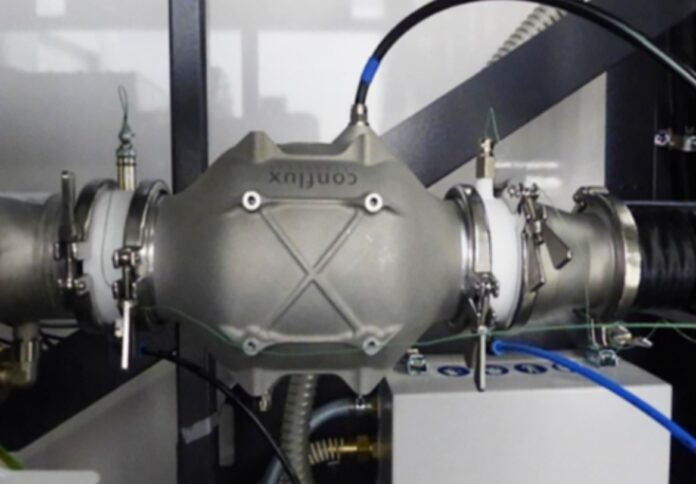

Through its AM-driven heat exchanger designs, Conflux creates components that are lighter, smaller, and capable of conforming to complex geometries.

By manufacturing these high-performance heat exchangers as single, unified parts, Conflux is able to optimise production efficiency, reduce material waste, and lessen the overall environmental impact.

“At Conflux Technology we pride ourselves on providing efficiency through heat transfer performance and weight-reduction at the heart of the world’s devices,” said Michael Fuller, Conflux’s Founder and CEO.

“With this additional funding and support, we will continue to advance our products and expand to support our customers across the globe.”

The investment will accelerate the development of Conflux Production Systems (CPS), an advanced, end-to-end AM solution for producing heat exchangers.

CPS integrates complex additive manufacturing structures into a seamless production line, replacing traditional heat exchanger manufacturing processes and providing clients with a streamlined, efficient, and resilient solution.

Conflux plans to expand its workforce and strengthen its presence in key markets across the United States, Europe, and Asia to meet growing demand.

Breakthrough Victoria’s CEO, Grant Dooley, underscored the significance of Conflux’s technology, saying, “Investing in Conflux and their revolutionary new heat exchanger technology signifies our commitment to sustainable innovation and efficiency.”

A leader in sectors ranging from motorsports and high-powered industrial machinery to hydrogen, e-mobility, and defence, Conflux Technology’s advanced solutions are capturing global attention.

Recently, the company partnered with Odys Aviation to contribute to the development of the next generation of regional VTOL (vertical take-off and landing) aircraft.

Leveraging Conflux’s AM capabilities, the collaboration aims to integrate a heat recuperator turbogenerator into Odys’ hybrid-electric VTOL aircraft, reducing fuel consumption by more than 40 per cent and enhancing efficiency.

James Dorris, co-founder and CEO of Odys Aviation, praised Conflux’s AM technology, stating, “Conflux’s additive manufacturing and metal 3D printing technology erase traditional design barriers, allowing us to bring geometrically complex and performance-optimized recuperator designs to life—ultimately resulting in longer-range and higher-payload aircraft. We’re excited to be working with Conflux’s team to redefine the capabilities of VTOL UAS systems.”

Conflux Technology said it is currently addressing a $6 billion global heat exchanger market, with plans to expand further through new partnerships and developments.