Precision Plastics Australia has unveiled DesignLab.au, a new platform designed to link global product designers with Australian additive manufacturing capability, in a move that reflects the growing shift toward locally produced, design-led consumer goods.

The Sydney-based company, which has spent the past five years expanding its industrial 3D printing operations, says the initiative demonstrates how manufacturing in Australia can remain competitive by focusing on speed, flexibility, creativity and just-in-time production.

In an exclusive interview with Australian Manufacturing, Dr Craig Morrison, founder of Precision Plastics and DesignLab.au, said the platform formalises a model the company has been refining since 2020, when supply chain disruptions and rising freight costs exposed vulnerabilities in traditional offshore manufacturing.

“DesignLab.au was built on a simple idea — that world-class design doesn’t have to be manufactured overseas,” Morrison said.

“By combining global creative talent with our advanced local production and retailer network, we’re proving that innovation, sustainability, and style can thrive together — right here at home in Australia.”

Design–manufacturer collaboration and workflow

According to Precision Plastics, the platform provides end-to-end support from digital design submission to local just-in-time manufacturing.

Morrison said the combination of high-volume additive manufacturing, digital collaboration systems and domestic distribution enables designers to bring products to market without sacrificing creative fidelity or production efficiency.

“We employ a number of prototyping processes, including close designer–manufacturer collaboration on materials, colours and textures, along with local production oversight to assure consistent quality,” he said.

“For efficiency, we scale by using just-in-time workflows across our large-scale print farm, employ batch process automation methods, a proven raw material base, and local vertically integrated supply chains to produce wonderful products from world-wide designers delivered on-demand to local retailers for sale to Australian consumers,” Morrison explained.

Production capacity and advanced additive technologies

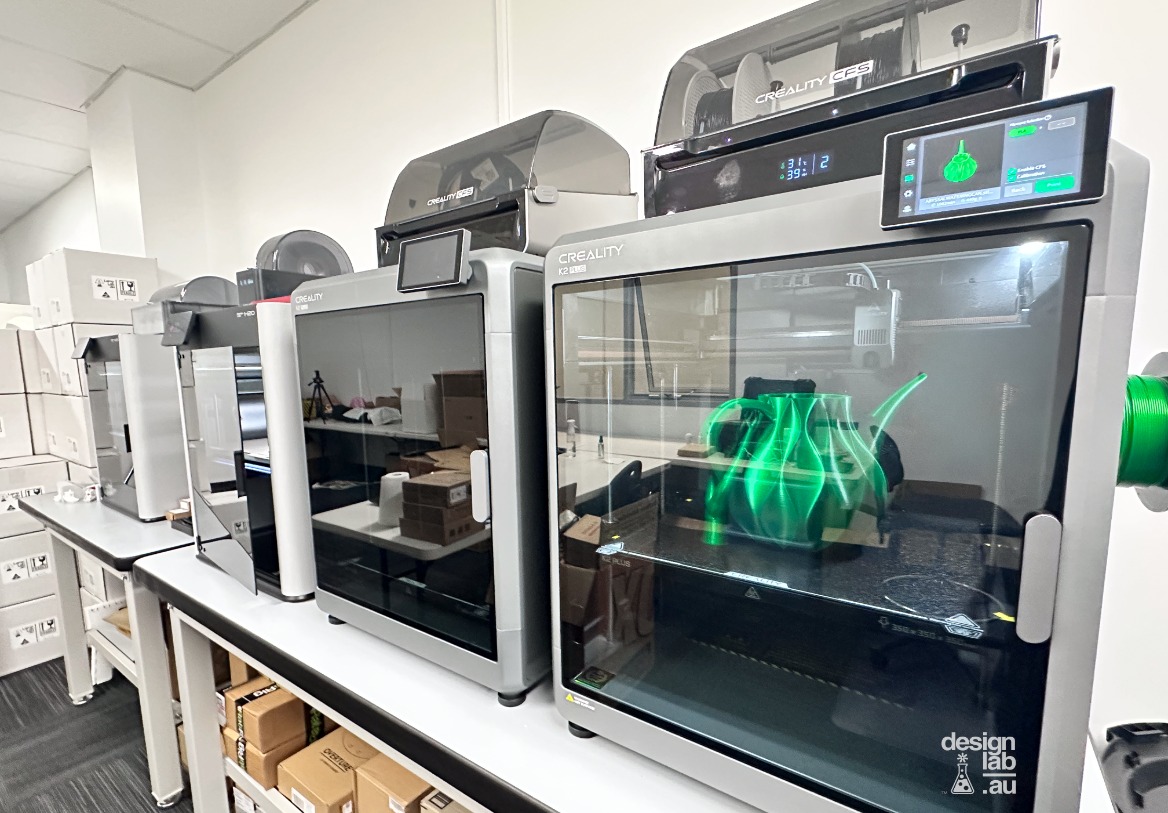

The company said DesignLab.au is underpinned by Precision Plastics’ production capacity, which includes more than 100 FDM and SLA printers from Bambu Lab, Raise3D, Prusa and Formlabs, operating in its Lane Cove facility.

It noted the printers support materials ranging from PLA and ABS to nylon and carbon-fibre composites, alongside laser CNC capabilities for hybrid production. Morrison noted that this scale allows the business to operate with the flexibility required for just-in-time manufacturing.

“Capacity and flexibility matter,” he said. “We can respond to demand fluctuations quickly. With a large fleet of printers, we can absorb designer and retailer needs and ramp up or down.”

Sustainability and material innovation through scale

Morrison said that scale is also playing a critical role in sustainability and material innovation. The company argues that localisation reduces transportation emissions, while on-demand production helps minimise waste created by excess inventory.

“Our large print farm means we can scale variations without massively increased cost/lead time,” he said.

He added that volume gives the company more scope to experiment with new materials, including recycled and recyclable plastics, composites and specialised finishes for home-décor applications.

“Without scale, the ability to offer many materials may well be uneconomic,” Morrison said. “Scale enables material innovation, more exotic finishes, custom colours and textures — all consistent with our DesignLab home-décor focus.”

Positioning Australia in design-led manufacturing

DesignLab.au, which is certified Australian Made and Owned, is positioned as a model for reshoring small- and mid-scale production by focusing on speed, agility and product distinction rather than low-cost mass manufacturing.

Morrison said the company sees opportunity in a model that avoids large batch sizes and long offshore supply chains. “While Australia can’t win the $0.05-per-part game, it can win the ‘make exactly what’s needed, quickly and beautifully’ game,” he said.

He said that design-driven products offer a manufacturing pathway less exposed to commodity-based competition. “When design is central, consumers and retailers focus less on cost and more on uniqueness, provenance and meaning,” Morrison noted.

What’s next

Precision Plastics said DesignLab.au aims to support an expanding network of designers and retailers, with products developed, printed and distributed from Sydney to locations nationwide.

“DesignLab.au isn’t just making products; strategically, it’s reframing what ‘Australian manufacturing’ means,” Morrison said.

The company said it welcomes new collaborators across design, retail and consumer markets as it continues developing locally produced collections for Australian homes.

For more information, visit the company’s website.