Manufacturing efforts to decarbonise global steel production received a further boost as Hazer Group Ltd announced it has extended its non-binding Memorandum of Understanding with POSCO Steel for two years, or until formal binding agreements are signed.

The extension, announced by Hazer, aims to progress work on integrating the company’s clean hydrogen and low-emissions graphite technology into POSCO’s low-carbon steel manufacturing pathway.

In an ASX release, Hazer said the decision follows a successful period of initial collaboration since the original MOU was signed in May 2024.

It noted that POSCO has been testing Hazer’s low-emissions graphite across a range of steelmaking and industrial applications, with the program continuing after “promising initial results.”

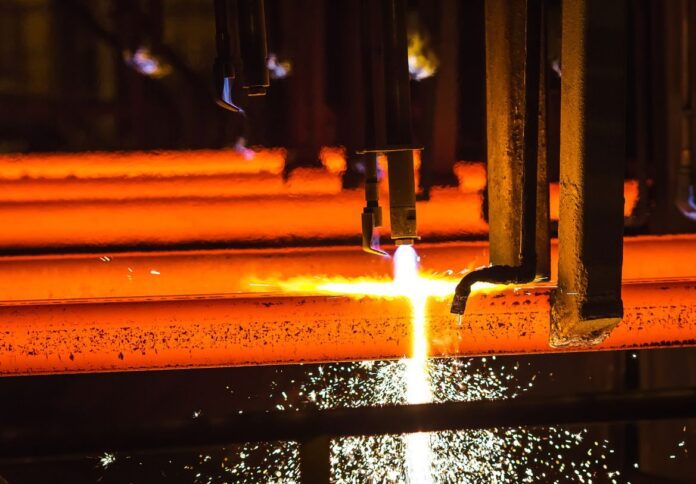

Hazer noted that steel manufacturing remains a carbon-intensive sector, accounting for more than 8% of global CO2 emissions.

The company said its technology offers a potential pathway to reduce emissions by co-producing low-cost clean hydrogen and high-purity graphite, using iron ore as a process catalyst.

The company added that it continues to engage with global steelmakers on opportunities to incorporate hydrogen and graphite into blast furnace operations and Direct Reduced Iron/Electric Arc Furnace steelmaking processes.

POSCO, headquartered in Pohang, South Korea, is claimed as one of the world’s largest steel producers and has committed to achieving carbon neutrality by 2050.

Haer said the group is pursuing growth across seven core business areas, including steel, rechargeable battery materials, hydrogen, energy and construction.

Hazer CEO and Managing Director Glenn Corrie said the extension strengthens the relationship between the two companies as the steel industry intensifies its decarbonisation efforts.

“We are very pleased to be extending our strategic collaboration with POSCO, one of the world’s largest industrial corporations leading the charge to decarbonise steel making,” Corrie said.

“Hazer technology’s unique features make it an excellent fit for low-carbon steel manufacturing, and we are excited to continue developing our partnership with POSCO alongside the growing interest in our technology across this important sector.”

The content of this article is based on information supplied by Hazer Group Ltd. For more information, please refer to the official company announcement and communications from Hazer. Please consult a licensed and/or registered professional in this area before making any decisions based on the content of this article.