Flinders University has joined the $270.5 million Additive Manufacturing Cooperative Research Centre (AMCRC), a national initiative focused on advancing Australia’s manufacturing capabilities through additive manufacturing.

With a $57.5 million contribution from the federal government, the AMCRC brings together 101 partners from research, industry and government to help transform and modernise manufacturing across sectors including defence, infrastructure, and medical technology, the university said in a news release.

Flinders University, a Core Partner in the seven-year AMCRC program, will support a range of research and industry-linked projects, including the development of sustainable concrete, the application of advanced manufacturing technologies, and the 3D printing of spinal implants for patients experiencing chronic pain.

Professor Raymond Chan, Deputy Vice-Chancellor (Research) at Flinders, said the initiative is aligned with the university’s priority to build sovereign capability and strengthen the national economy through innovation in manufacturing.

“Our cutting-edge research will help drive the broader adoption and growth of advanced manufacturing technologies, enhancing critical industry sectors as part of an innovation ecosystem,” Professor Chan said.

Flinders’ Professor David Lewis, a lead on the CRC, said the initiative will support the university’s ongoing commitment to manufacturing through the Flinders Factory of the Future, which works in partnership with the Institute for Nanoscale Science and Technology and the Medical Device Research Institute (MDRI).

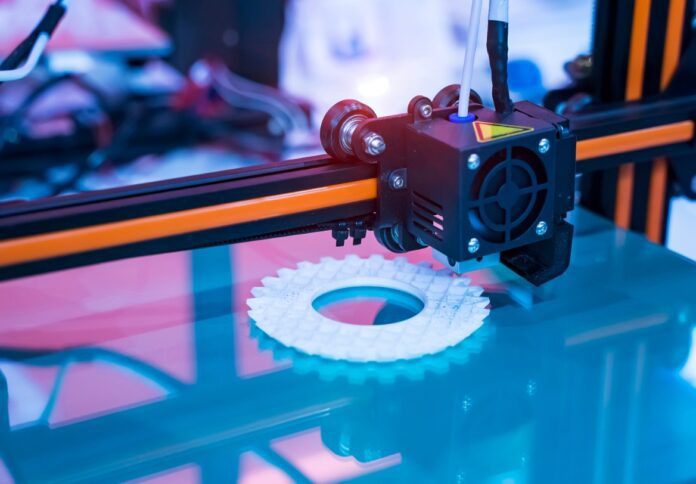

“The AMCRC will transform additive manufacturing, more commonly known as 3D printing, from an approach that has predominantly been used for non-critical and prototype items to a method for mainstream manufacturing and on-demand production of high performance, highly customisable precision parts and components,” Professor Lewis said.

The AMCRC has already gained traction within the business community, with 73 small and medium-sized manufacturers and three industry associations on board to adopt emerging technologies and improve the sustainability of local supply chains.

Professor Claire Lenehan, Director of the Flinders Factory of the Future, welcomed the funding, stating: “The potential of additive manufacturing is enormous, and we are excited by this investment in advancing additive manufacturing.”

Flinders’ MDRI, led by Professor Karen Reynolds, is spearheading the development of cutting-edge medical technologies, including a collaboration with Additive Surgical to produce 3D printed spinal implants.

Made in Adelaide using titanium, the implants feature advanced biomimetic lattice structures designed to integrate seamlessly with human bone.

“These implants… are life-changing medical devices,” said Professor Reynolds.

Gibran Maher, CEO of Additive Surgical, added that additive manufacturing is fundamentally changing how implantable devices are made.

“By leveraging biomimetic design and integrating multiple lattices within a single implant, we are pushing the boundaries of innovation in surgical solutions,” he said.