German hydrodynamic service and consulting firm Hamburg Ship Model Basin (HSVA) has managed to significantly reduce the time and cost to produce bespoke prototype ship model components with the introduction of Stratasys’ Objet Eden350V printer to its manufacturing process.

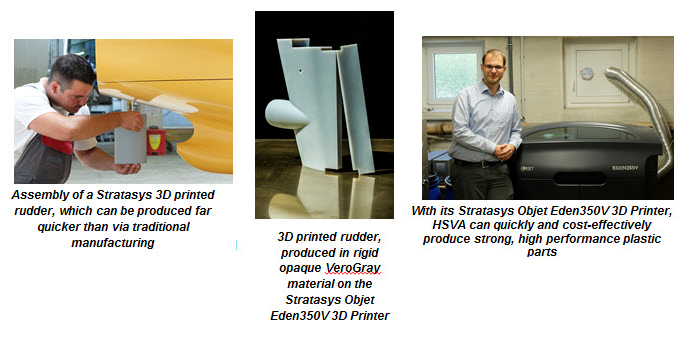

Privately-managed and independent HSVA, which previously outsourced its 3D printing requirements, decided to bring Stratasys’ manufacturing technology in-house to quickly and cost-effectively produce strong, high performance plastic prototype parts while upholding its high standards of quality and precision.

“A full-size ship is a complex geometric form with many complicated shapes that have to be re-produced true-to-scale,” said Michael Neumeier, Mechanical Design Engineer at HSVA.

“To traditionally manufacture a prototype ship rudder in wood or plastic is a very skilled and labour-intensive job and typically takes up to three weeks to produce. With our Stratasys 3D Printer, we can produce parts within a day, which after cleaning, are ready for final assembly.”

He said the Objet Eden350V gave HSVA far greater flexibility in dealing with customer requests – including the implementation of last minute changes – and in the production of the case for model azimuth propulsor drives (also known as “Pods”), one of the most advanced marine propulsion systems which are typically very difficult to produce and assemble.

“Being able to print the various parts on our Stratasys 3D Printer makes assembly much easier. This has seen us slash lead times by as much as 70 percent, which has resulted in significant cost reduction of around 30 percent,” Mr Neumeier added.

According to the Stratasys press release, all 3D printed components are produced in VeroGray, which is a rigid opaque material that provides “excellent dimensional stability, great detail visualisation and a sufficiently smooth surface quality.”

Thanks to the one-of-a-kind combination of extreme precision and high material strength, VeroGray models are able to withstand the rigorous testing procedures undertaken by the company.

“It’s now difficult to imagine life without our in-house 3D printing capability. Stratasys has been extremely supportive during installation, and the technology is now being used in almost every department. Not only have we cut lead times and costs, but the need for less human intervention throughout prototype production ensures maximum process stability and reliability,” said Neumeier.

“The integration of our additive manufacturing technology at HSVA in Germany and the incredible difference it is making to their design and production process is indicative of the efficiencies enjoyed by customers across a host of industries. Material advancements in particular enable the production of tough, realistic prototypes that can endure rigorous functional testing during the development phase,” concluded Andy Middleton, President of Stratasys EMEA.