IperionX Limited, a producer of sustainable titanium technology, has signed a deal with Heroux-Devtek, a Canadian aerospace company, to support a 100 per cent recycled titanium supply chain based on scrap titanium metal from the aerospace industry.

Heroux-Devtek is a global aerospace company that specialises in the design, development, manufacture, and maintenance of landing gear, actuation systems, and components.

As part of the agreement, Heroux-Devtek will provide IperionX with scrap Ti-6Al-4V alloy metal produced during the manufacture of landing gears.

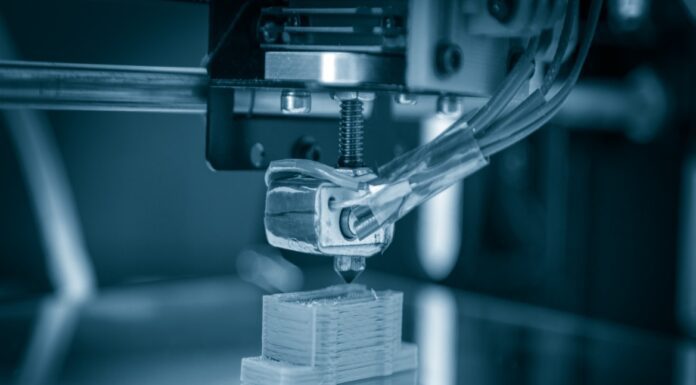

This titanium scrap will then be processed by IperionX using its patented titanium processing technology to create low-carbon titanium for upcoming uses.

Aperam / ELG Utica Alloys will handle the processing of the Heroux-Devtek titanium scrap as part of their current collaboration with IperionX.

Dominique Dallaire, Heroux-Devtek vice president of Central Division, expressed his excitement to expand on the partnership and investigate the possible use of fully circular recycled titanium metal in the company’s future operations.

“The partnership between Heroux-Devtek and IperionX establishes a new benchmark in the sustainability of the aerospace supply chain through the development of low-carbon titanium materials for North American markets,” Dallaire noted.

IperionX CEO Anastasios Arima also expressed his delight over the collaboration that will pave the way for the development of a sustainable, circular titanium supply chain for advanced US industries.

“This partnership with Heroux-Devtek provides IperionX with a diversified, long-term supply of titanium feedstock for the production of American titanium and will enhance the sustainability of the aerospace supply chain,” Arima said.

The ASX-listed company revealed its proprietary titanium production technologies consume less energy, cost less, emit no Scope 1 or 2 pollutants, and offer a route to sustainable manufacture of titanium by using only 100 per cent scrap titanium as a feedstock.

Notably, additional high-performance titanium alloys, such as Ti-5553 and Ti-10-2-3, which are prized for their fracture toughness and strength, are also used in aircraft sector landing gears.

These titanium alloys can be recycled using IperionX’s technologies, obviating the requirement for a remelt procedure and enabling their use in a variety of new high-performance applications.