Queensland University of Technology (QUT) has announced an $18 million upgrade to its Pioneer BioPilot facility in Mackay, aiming to establish the state as a leading hub for biomanufacturing in the Asia-Pacific region.

The upgraded QUT Pioneer BioPilot, backed by funding from the Australian and Queensland governments and developed with Australia’s Food and Beverage Accelerator (FaBA), is being described as Australia’s leading pilot-scale fermentation facility, QUT said in a news release.

The university noted the project is aimed at enabling companies to collaborate with QUT researchers to develop new food products and bioproducts, offering both dietary alternatives and sustainable solutions to agricultural challenges.

Senator Corinne Mulholland said the initiative would help cement Australia’s role in the global bioeconomy, valued at USD 4 trillion and expected to reach US$30 trillion by 2050.

“This investment positions Australia as a serious player in the global bioeconomy and, importantly, it will make Mackay one of the driving forces for our future economy,” Senator Mulholland said.

“The Albanese Government has been clear that this transition is not just an investment in our planet, but an investment in the jobs, skills and technology of tomorrow. These facilities are a clear demonstration of that,” she added.

QUT Centre for Agriculture and the Bioeconomy researcher Professor Ian O’Hara said the facility builds on 15 years of pioneering work translating research into real-world applications, including converting sugarcane by-products into biofuels and green chemicals.

“The QUT Pioneer BioPilot is pioneering research and innovation in biomanufacturing, working with government and industry to position Queensland as a globally connected innovation hub,” Professor O’Hara said.

“QUT is leading regional innovation across Queensland, empowering communities and driving sustainable economic growth. Real-world impact is at the heart of QUT’s research commitment, where knowledge and innovation tackle global challenges and deliver locally grounded solutions.”

Assistant Minister for Primary Industry Development, Water and Western Queensland Sean Dillon said the expansion of the facility highlighted Queensland’s ability to transform agricultural output into high-value products.

“The upgraded MRBPP gives local researchers and industry the tools to turn biomass into high-value products – right here in Mackay,” Dillon said.

“It’s a powerful demonstration of how regional Queensland is open for business, strongly appealing to companies looking to use sugar feedstocks for their products.”

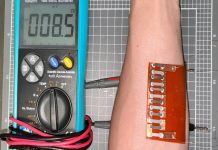

Professor O’Hara, who is also Deputy Dean of the QUT Faculty of Engineering, said fermentation bioreactors were a standout feature of the facility, allowing companies to fast-track product development.

“This facility will enable innovative companies to take their ideas beyond the lab and into commercial reality, building Queensland’s reputation as a regional leader in biomanufacturing,” he said.

FaBA Director Dr Chris Downs said the QUT Pioneer BioPilot would provide vital infrastructure for businesses nationwide. “The QUT Pioneer BioPilot provides key infrastructure, allowing companies to take new innovations from the lab to pilot-scale,” Dr Downs said.

“FaBA is investing in precision fermentation so that companies of all sizes can develop new products and ingredients, in turn helping grow Australia’s food and beverage manufacturing sector.”

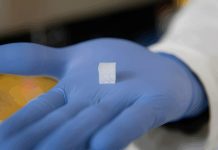

QUT is also collaborating with Eclipse Ingredients and other institutions on a $5.5 million project to commercialise human lactoferrin, a protein found in breastmilk with immune-boosting properties. Eclipse Ingredients CEO Siobhan Coster said QUT’s expertise was central to the project’s success.

“The partnership with QUT is crucial because it bridges the gap between breakthrough science and real-world impact,” Coster said.

“It allows us to scale our product and process from lab to commercial readiness right here in Queensland, Australia.”