Canberra-based advanced manufacturing company New Frontier Technologies (NFT) is progressing a series of high-performance composite projects for the space sector, according to a joint media release.

The company is working with the Department of Education’s iLAuNCH Trailblazer program to advance carbon composite structures designed for precision space applications.

The release said NFT specialises in the design, additive manufacturing and digital twinning of advanced carbon composite structures, using automation and digital tools to shorten development cycles. Its technologies support both bespoke, low-volume work and scalable production through additive processes.

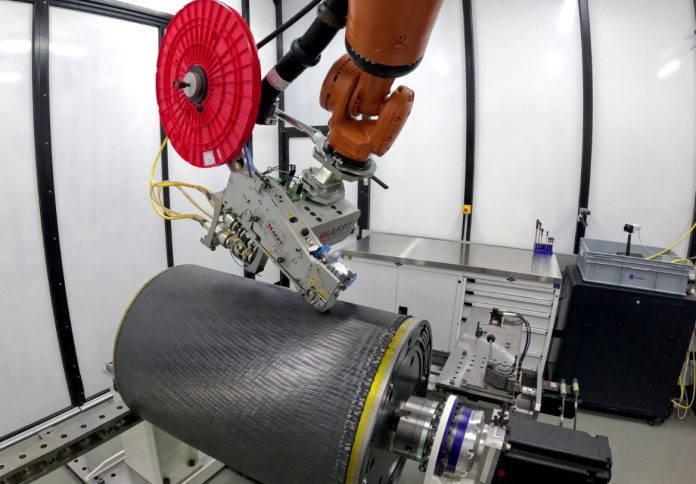

NFT has also pioneered laser-assisted automated fibre placement, described as a clean additive manufacturing method for producing thermoplastic composite structures with near-zero thermal expansion.

According to the statement, this capability is critical for instrumentation and optical systems that must remain stable under extreme temperature variations.

Projects underway through iLAuNCH include a composite rocket body with a structural digital twin, which has completed vibration testing to NASA’s sounding rocket qualification standards.

NFT is also designing and manufacturing optical mounts and telescope structures for space and ground-based observatories, including equipment for the KECK Observatory, the DREAMS telescopes and the OzFuel satellite. Work on composite structures for European Southern Observatory instrumentation is scheduled to begin in 2026.

NFT CEO and Director Dr Paul Compston said national collaboration has been central to the company’s progress.

“Working alongside university and industry partners through the iLAuNCH Trailblazer has allowed us to take our design and manufacturing processes to the next level, meeting the demanding performance and verification requirements of the space environment,” Dr Compston said.

He said the company’s digital design and verification capabilities are supporting improvements in Australian-built systems.

“Our ability to design and digitally verify thermally stable, lightweight composite structures is enabling new levels of performance for Australian-built space systems,” he said.

The release noted that NFT’s digital twinning platform, DigiTwin, received the JEC World 2025 Innovation Award in the Digital, AI and Data category.

Its composite rocket project through iLAuNCH was also named R&D Project of the Year at the 2025 Australian Space Industry Awards.

NFT is now extending its advanced composites work to aerospace, defence, marine and clean energy applications.

“The precision, performance, and digital assurance we’ve developed for space are directly transferrable to other demanding applications,” Dr Compston said, adding that the company aims to see “Australian-made composite structures playing a vital role in future global space missions and beyond.”