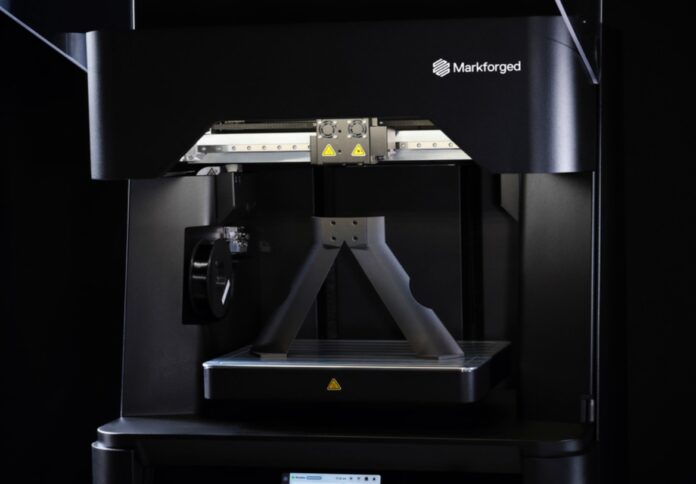

Additive manufacturing company Markforged has unveiled its newest industrial 3D printer, the FX10, designed to enhance manufacturing productivity and efficiency while offering significant cost savings at the Formnext 2023 event.

In a press release, the company said the FX10 allows users to create parts on-demand, reducing costs and cutting lead times dramatically compared to traditional manufacturing methods.

Shai Terem, CEO of Markforged, emphasised that they designed the FX10 to be the optimal tool for the manufacturing floor.

“The FX10 allows manufacturers to slash original part replacement costs when compared to traditional methods and keep production lines running without worrying about supply chain issues or spare parts inventory,” Terem remarked.

It also ensures uninterrupted production by mitigating concerns related to supply chain issues and spare parts inventory.

Terem said he believes that the FX10 can expedite the digitisation of the manufacturing floor through greater adoption of digital inventory, thereby enhancing supply chain resilience.

“Our customers now have the potential to save even more capital by reducing physical inventory and boosting production yields while decreasing operating costs,” he explained.

According to Markforged, the FX10 is designed with modularity in mind, offering expansion and upgrade options to meet various needs.

It features a Continuous Fiber Reinforcement (CFR) print system that delivers high print quality in a heated print chamber, resulting in faster print speeds and larger print sizes compared to previous Markforged industrial series printers.

Terem highlighted the significance of this release, stating, “The FX10 is another important milestone in our mission to bring industrial production to the point of need. It enables our customers to address even more industrial applications with clear return on investment.”

Furthermore, the printer incorporates optical sensors for dimensional accuracy verification, machine health and performance assessment, and laser micrometry for scanning and calibration.

Inspection software interprets data from these sensors, providing quality assurance upon completing a print.

The FX10 simplifies the user experience with a touchscreen interface and new automation technologies, requiring fewer interactions by the operator before and during a print.

The printer also features a material drawer with built-in storage bays for filament spools, enabling automatic spool changeovers during a print.