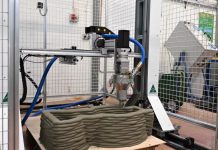

Markforged’s FX20 3D printer made its Australian debut at the Swinburne University of Technology.

In a media release, Swinburne University said the FX20 printer is designed for high-strength end-use parts in the aerospace, defence, automotive, and energy industries.

The 3D printer is capable of printing nearly five times larger builds, with speeds eight times faster than Markforged’s existing line of composite printers.

“Supply chain issues can be costly and time-sensitive for Australian businesses. The FX20 will provide a competitive advantage to manufacturers by allowing them to react quickly to solve problems right on the manufacturing floor,” Richard Elving said, Markforged’s senior director for Australia.

The FX20 printer is also equipped with a heated build chamber capable of maintaining a temperature of up to 200°C to print flame-retardant, high-performance thermoplastic material.

Swinburne’s Aerostructures Innovation Research (AIR) Hub will house the FX20 printer, making it the first and only FX20 printer openly accessible to Australian manufacturers for use in research and development.

“This state-of-the-art printer will be a game-changer for Australian businesses,” said AIR Hub Director Adriano Di Pietro.

The solution is also expected to help promote new aerospace development and provide a boost for the local sector.

AIR Hub hosted the launch of the new printer at the Factory of the Future in Victoria on 25 October. The event is part of a three-city launch tour in Melbourne, Perth, and Sydney.

“AIR Hub is bringing industry together with cutting-edge technology to support the growth of aviation and aerospace in Australia. We’re proud to be hosting Australia’s first openly accessible FX20 in Swinburne’s Factory of the Future,” Di Pietro added.

“The FX20 is a beast of a machine, enabling the robust production of lightweight, advanced composite parts,” according to Shai Terem, president and CEO of Markforged.

“With this combination of hardware and software, users can create end-use, mission-critical parts and build resilient and sustainable supply chains that extend directly to the point of need,” Terem said.