Photo-chemical etching (PCE) has become a popular choice for component manufacturers in the aerospace, medical, and electronics industries as it enables the production of intricate shapes and patterns with high precision.

The process uses chemicals to erode areas of sheet metal to form the shape of a required part or component and needs strict process controls to ensure quality as any deviation can result in defective components and compromised functionality and safety in the final product.

Michael Kern, head of quality management at PCE innovator micrometal, highlighted how the company maintains its compliance with tight tolerances and consistent quality standards for components in order to meet customer demands.

Control means quality

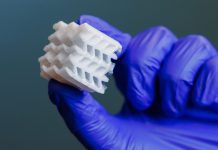

micrometal manufactures products that are far from the usual parts fabricated from metal. These components are often geometrically complex and need to be produced with maximum repeatability, which can only be achieved efficiently with PCE.

According to Kern, quality is at the heart of what his company does as its performance directly impacts how efficiently, over a long period of time, customers’ assembly lines will operate without incidents.

In order to maintain efficient production, micrometal has established control measurements in all areas of production and created a highly reliable supplier base.

“Imagine one defective part or section on a reel one kilometre in length — taking hours to produce — and resulting in the reel needing to be scrapped. Also, we usually do not have one reel being produced at any one time, but several reels simultaneously in a continuous process, meaning we cannot just simply stop production. We cannot remove the defect and continue,” Kern explained.

Detecting defects and changing the game

No manufacturing process is faultless at first and defects in PCE defects cannot be totally eliminated. To address this, micrometal has tapped into technologies designed to detect defects during production and take counter-measures to keep the yield high.

“As our market-leading PCE process is pushing the boundaries of what is possible with etching, quality control technologies are also operating at the edge of their capabilities in a production setting. Because of this, we undertake 100% inspection of our products in a downstream process so that we can be really confident that we have achieved the quality we promised our customers,” Kern said.

For the company, 100% Inspection is a downstream quality process that involves all necessary efforts to re-check every part manufactured with the best technologically available resources.

This inspection is intended to achieve maximum repeatability, reproducibility, and reliability of product output.

“In etching, like in any other production method, there can always be a deviation. But, with all control methods put into place we minimize failures as far as is technically possible,” the micrometal executive said.