![Lamination tool for a drone fuselage[82] (1)](https://www.australianmanufacturing.com.au/wp-content/uploads/2025/12/Lamination-tool-for-a-drone-fuselage82-1-696x484.jpg)

Military UAV sub-assembly and airframe manufacturing company KTEK Systems has completed a $2.5 million oversubscribed seed capital raising, exceeding its initial $1.5 million target, according to Chapter One Advisors.

In a news release, the firm shared the manufacturing-focused raise is intended to support production scale-up and preparation for a planned ASX initial public offering in the first quarter of 2026.

It noted that the seed round attracted participation from Australian small-cap funds, family offices and high-net-worth investors, with Regal Emerging Companies Fund acting as a cornerstone investor.

The capital was raised via a convertible note that will convert at a fixed price of 10 cents, representing a discount to the company’s planned IPO price of 20 cents.

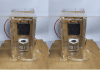

Chapter One Advisors said the funds would be directed toward expanding KTEK’s global manufacturing footprint, advancing its proprietary “Cordless Factory” production model, and supporting IPO readiness.

KTEK, which supplies full-turnkey sub-assemblies and composite airframes to military UAV original equipment manufacturers, also plans to enter an exclusive option agreement to acquire KTEK Ltd in Israel at the time of listing, consolidating its manufacturing and engineering operations ahead of the proposed IPO.

Founder and chief executive Dekel Keisar said the capital raising reflects investor confidence in the company’s manufacturing platform and its position within the global UAV supply chain.

“The oversubscription reflects strong conviction in our technology, our operating model, and the strategic role KTEK plays within the global UAV supply chain,” Keisar said, adding that the funding would allow the company to “scale with our customers as they expand production capacity worldwide.”

Chapter One Advisors noted that KTEK operates a capital-efficient manufacturing model that combines in-house engineering and quality assurance with a network of certified production partners across multiple regions.

The adviser said this approach is designed to deliver aerospace-grade manufacturing outcomes while limiting fixed overheads, positioning the company to respond to increasing global demand for military UAV systems.