MIT engineers have developed a 3D-printable aluminium alloy that is significantly stronger and more heat-resistant than conventional aluminium, a breakthrough that could support the development of lighter components for aerospace and other industrial applications, according to the institute.

In a media release, MIT said the alloy, produced using additive manufacturing, is five times stronger than traditionally cast aluminium and matches the strength of the strongest aluminium alloys currently made through conventional methods.

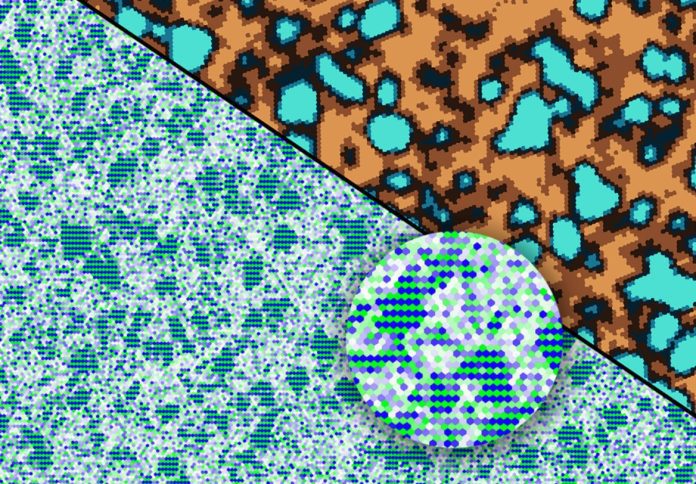

The material was designed using a combination of simulations and machine-learning techniques to identify an optimal mix of aluminium and other elements.

Researchers said machine learning enabled them to dramatically reduce the number of alloy compositions that needed to be evaluated. Instead of simulating more than one million possible combinations, the team assessed just 40 compositions before identifying a suitable high-strength alloy.

“With machine-learning tools, they can point you to where you need to focus,” said Mohadeseh Taheri-Mousavi, who led the work as a postdoctoral researcher at MIT. “It lets you explore the design space more efficiently.”

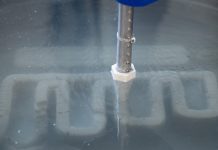

According to MIT, the alloy’s strength comes from its microstructure, which contains a high density of very small precipitates. The researchers found that laser powder bed fusion, a form of metal 3D printing, enabled rapid cooling that preserved this fine microstructure, something that is more difficult to achieve through traditional casting.

“Here, 3D printing opens a new door because of the unique characteristics of the process — particularly, the fast cooling rate,” said John Hart, head of MIT’s Department of Mechanical Engineering.

The researchers suggested the printable aluminium could be used in applications where strength, weight and temperature resistance are critical, including aircraft components, vacuum pumps and data-centre cooling systems.

Taheri-Mousavi noted that lighter materials could have broader implications for efficiency, saying, “If we can use lighter, high-strength material, this would save a considerable amount of energy for the transportation industry.”

MIT said the findings were detailed in a paper published in Advanced Materials and involved collaborators from Carnegie Mellon University and Paderborn University in Germany.

The researchers cautioned that further work is ongoing to optimise additional properties of the alloy, but said the approach demonstrates how machine learning and additive manufacturing can be combined to accelerate the design of advanced materials.