NASA said it is eyeing two new institutes to advance technology critical to engineering and climate research as the space agency plans to develop multidisciplinary research and technology programs to support long-term exploration goals.

The two new Space Technology Research Institutes (STRIs), which will receive up to $15 million over five years, will be led by teams from universities in the United States, NASA said in a press release.

One of the research institutes will concentrate on quantum sensing technology to aid climate research.

The other will work to improve understanding and speed up the certification of metal parts made with advanced manufacturing techniques.

The Quantum Pathways Institute, led by the University of Texas at Austin, will advance quantum sensing technology for next-generation Earth science applications.

This type of technology would allow for a better understanding of our planet and the effects of climate change.

The institute will also strive to enhance the physics underpinning quantum sensors, develop designs for these sensors that may be used in space missions, and comprehend how mission design and systems engineering must change to accommodate this new technology.

“Quantum sensing methods have shown a great deal of promise in computing, communications, and now for Earth science remote sensing applications,” said Dr Srinivas Bettadpur, principal investigator for the institute and professor of aerospace engineering and engineering mechanics at the University of Texas at Austin.

Partners on the institute include the University of Colorado Boulder; the University of California, Santa Barbara; the California Institute of Technology; and the National Institute of Standards and Technology.

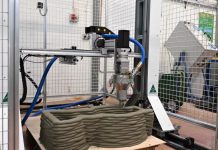

The Institute for Model-based Qualification & Certification of Additive Manufacturing (IMQCAM), on the other hand, is led by Carnegie Mellon University in Pittsburgh and aims to enhance computer models of 3D-printed metal parts and increase their use in spaceflight applications.

“The institute will focus on creating the models NASA and others in the industry would need to use these parts on a daily basis,” said Tony Rollett, principal investigator for the institute and US Steel professor of metallurgical engineering and materials science at Carnegie Mellon University.

The institute will be co-led by Johns Hopkins University in Baltimore.

The centre will also evaluate and simulate new materials in addition to creating digital twins for 3D-printed components produced from materials typically used in spaceflight.

“We’re thrilled to draw on the expertise of these multi-university teams to create technology for some of our most pressing needs,” said Jim Reuter, associate administrator for the agency’s Space Technology Mission Directorate at NASA Headquarters in Washington.

“Their work will enable next-generation science for studying our home planet and broaden the use of 3D-printed metal parts for spaceflight with state-of-the-art modelling,” Reuter added.